مهندسی روشنایی، راهحل یکپارچه روشنایی، روشنایی LED، روشنایی جاده، روشنایی منظر، روشنایی نمای ساختمان، روشنایی جشنواره، روشنایی کارگاه، روشنایی فرهنگی-توریستی، نشانههای روشن

فنی طرح و راهنمای اجرای پروژه سیستم فوتوالکتریک خارج از ساختمان برای مال تجاری

هدف سند: هماهنگی مناقصه، اجرای پروژه، اطلاعرسانی فنی

سناریوهای کاربردی: پروژههای روشنایی نمای ساختمان و پشت بام، پروژههای خارج از کشور در مصر

محدوده اصلی: ادغام نقشههای CAD، تجهیزات روشنایی سری RGBW (چراغهای شستشوی دیواری، فلودلایتها، چراغهای نصبشده روی پایه، چراغهای تعبیهشده در کف یا سقف، چراغهای فواره)، نمای بامی روشنشونده BERMILLAN، سیستمهای کنترل و مهندسی لولهکشی/مدار

استانداردهای سازگاری: مطابق با مشخصات بینالمللی نصب مهندسی، سازگار با ولتاژ محلی مصر (220 ولت/50 هرتز)، شرایط آبوهوایی و الزامات فرهنگی، و همچنین رعایت دقیق استانداردهای ساختمانی، الکتریکی و دسترسی به محصولات مصر

1. پیششرایط پروژه: فهرست مدارک اصلی مورد نیاز توسط مشتری

برای اطمینان از اجرای دقیق بررسی نقشهها، ادغام فنی، برنامهریزی لولهکشی و طراحی اثرات نوری، مشتری باید مدارک اصلی زیر را بهصورت پیشنهادی ارائه دهد. ما این مدارک را بهصورت یکپارچه ثبت و بایگانی کرده و بهعنوان پایهای برای طراحی فنی مورد استفاده قرار خواهیم داد.

1.1 مواد اصلی نقشه

- نقشههای معماری: نقشههای اجرایی نمای مرکز خرید، نقشههای سازه سقف، نقشههای گرههای دیوار پردهای (همراه با مشخصات مواد و ضخامتها)، و جزئیات سازه پیشبام (در فرمتهای DWG و PDF).

- نقشههای چیدمان محل: نقشه کلی فضای بیرونی (شامل موقعیت فوارهها، چیدمان ستونهای پیشبام، مسیرهای پیادهرو و مسیر لولهکشی زیرزمینی)، و نقشه طبقه بام (با مشخص کردن مناطق نصب حروف روشن و نقاط تحمل بار).

- نقشههای فونداسیون برق: شامل نقاط اصلی برق قوی و ضعیف در ساختمان، موقعیت تابلوهای توزیع همراه با مشخصات ظرفیت، و نقشههای سیستم ارتینگ.

- نقشههای تکمیلی اضافی: برای هر نقطه نورپردازی رزرو شده یا لولهکشی پیشبینی شده، باید نقشههای طراحی مربوطه و عکسهای اندازهگیری محلی ارائه شوند.

1.2 دادههای پارامترهای پایه

- مشخصات سایت: ابعاد دیوار نمای ساختمان (ارتفاع/عرض)، مشخصات ستونها (قطر/ارتفاع)، محل نصب نمای تبلیغاتی روشناییدار روی پشت بام، و ابعاد استخر فواره (عمق/مساحت).

- نیازمندیها: تعیین افکتهای مورد نظر برای حالت روزهای هفته، تعطیلات و پرچم ملی، الزامات برنامهریزی روشنایی و نیازمندیهای کنترل منطقهای.

- مدارک انطباق: مدارک تأیید پروژه محلی در مصر، دستورالعملهای پیشتصویب مجوزهای ساخت و نصب و الزامات تنظیمی برای تأیید مصرف برق.

1.3 فرآیند تحویل و ثبت دادهها

- پس از دریافت مواد از سوی مشتری، ما سازماندهی و طبقهبندی آنها را ظرف مدت 3 روز کاری تکمیل خواهیم کرد و کامل بودن مدارک را بررسی کرده و هرگونه مدرک مفقودی را شناسایی میکنیم.

- در مورد نقشههای مبهم یا ناقص، «اعلان مدارک تکمیلی» صادر خواهد شد. فرآیند ادغام فنی تنها پس از تکمیل مدارک مورد نیاز توسط مشتری آغاز خواهد شد.

- تمام مواد اصلی توسط پرسنل اختصاصدادهشده ما آرشیو و مدیریت میشوند و به عنوان مرجع اصلی برای طراحی پروژه، ساخت و تحویل مورد استفاده قرار میگیرند.

2. تجزیه فاز اجرای پروژه (محتوای کلیدی کار تیم ما)

مرحله اول: ثبت دادهها و یکپارچهسازی و بهینهسازی نقشهها

2.1.1 ثبت و بایگانی دادهها

ما به صورت سیستماتیک نقشهها و پارامترهای فنی ارائهشده توسط مشتری را ثبت میکنیم و همزمان از نسخههای الکترونیکی و کاغذی آنها نیز بایگانی به عمل میآوریم. هر سند با شماره نسخه، تاریخ دریافت و دستهبندی هدف برچسبگذاری میشود تا قابلیت ردیابی و تأیید آن تضمین شود و از انحرافات طراحی جلوگیری گردد.

2.1.2 یکپارچهسازی و بهینهسازی نقشههای CAD

بر اساس نقشههای اصلی ارائهشده توسط مشتری، کارهای یکپارچهسازی و بهینهسازی زیر را انجام دادهایم تا یک سیستم یکپارچه نقشهکشی اجرایی برای پروژه ایجاد شود:

- بهروزرسانی نقشهها: تکمیل نمودارهای نقطهی روشنایی و نقشههای پیشنگهداری خطوط لوله با دادههای بررسی میدانی (در صورت نیاز)، مشخص کردن تمام تجهیزات (شامل چراغهای دیواری، چراغهای فرو رفته و چراغهای فواره) همراه با نقاط نصب، فاصلهگذاری و ارتفاع آنها.

- مشخصات پارامترها: ابعاد باید با دو واحد اندازهگیری (متریک و امپریال) درج شوند، همراه با استانداردهای بینالمللی مواد (مانند فولاد ضدزنگ 304 مطابق ASTM A240، فولاد قوطیای شماره 8 مطابق ES 2629)، اتصالات ضدآب و دادههای تأیید باربرداری که با مشخصات مصری سازگار باشد.

- وسایل کمک آموزشی تصویری: شامل نمودارهای اثرات نورپردازی پویا، نقشههای پوشش پرتو و نمودارهای نقطهی رنگ پرچم مصر بهمنظور اطمینان از تطابق نقشهها با الزامات بصری.

- مشخصات فرمت: خروجی یکنواخت از فایلهای AutoCAD.dwg و PDF با لایههای خطی واضح، جزئیات گرهها در مقیاس ≥1:20، و فیلدهای رزرو شده برای امضای مشتری و بازبینی توسط طرف ثالث.

مرحله 2: طراحی و یکپارچهسازی راهحل فنی

2.2.1 ادغام فنی سیستمهای روشنایی

با ترکیب نیازمندیهای مشتری با استانداردهای آبوهوایی و انطباق مقرراتی مصر، مستندات فنی استاندارد شده را از طریق راهکارهای جامع برای تمام تجهیزات روشنایی توسعه میدهیم که شامل انتخاب، نصب و بهینهسازی عملکرد میشود.

- شستشوی دیواری RGBW: با مشخصات مدل 36 وات، زوایای نصب کالیبره شده، بازتولید دقیق رنگ پرچم مصر و راهکارهای جامع روشنایی نمای ساختمان.

- سیستم روشنایی ستون: با نصب یکپارچه اسپات لایت RGBW 24 واتی و فناوری روشنایی مکمل برای توزیع یکنواخت نور.

- لامپ کف فرو رفته RGBW 24 وات: دارای نصب پیشساخته یکپارچه ( bedding شن + لنگر بتنی)، درجه مقاومت در برابر آب IP67 و فناوری طراحی ایمنی ضد ضربه.

- چراغ فواره: با مقاومت در برابر آب یکپارچه IP68، اثرات همزمانشده شلتاب آب و فناوری آببندی کابل زیرآبی.

- نمایشگر روشن BERMILLAN: با ارتفاع 4 تا 6 متر، ضخامت 30 تا 40 سانتیمتر، پوسته فولاد ضدزنگ 304 و ساختار فناوری فولاد کانالی 8 میلیمتری، که ادغام بیدرز با سازههای سقف را تضمین میکند.

2.2.2 ادغام فناوری سیستم کنترل

سیستم کنترل DMX512/Art-Net از فناوری ارتباط جهانی بهره میبرد تا تعویض دقیق حالتها را فراهم کند:

- ادغام حالت: منطق تعویض را برای سه حالت یکپارچه میکند —روزانه (نور سفید گرم)، جشنواره (نور رنگی پویا) و پرچم خاص مصر (قرمز، سیاه و سفید ثابت/پویا) —در حالی که دنباله عملیات تمام تجهیزات روشنایی را همگام میکند.

- کنترل ناحیهای: ماژولهای کنترل مستقل برای مناطقی از قبیل سایبانها، نماها، سقفها و فوارهها طراحی شده است که از تنظیم فردی و همچنین عملیات هماهنگ پشتیبانی میکنند. کنترلکننده اصلی ≥10 برنامه سفارشی را به صورت آفلاین ذخیره میکند.

- سازگاری عملیاتی: ادغام دکمههای دستی (جعبه توزیع) با سوئیچ خودکار زمانبندیشده به منظور سادهسازی فرآیندها و برآوردن نیازهای نگهداری در محل در مصر.

مرحله ۳: طراحی و ادغام سیستم مدار لولهکشی

۲.۳.۱ برنامهریزی و طراحی مدار لولهکشی

ما طراحی و ادغام یکپارچه سیستمهای لولهکشی و الکتریکی را تکمیل کردهایم و از این طریق ایمنی، پنهانسازی و مقاومت در برابر شرایط آبوهوایی را تضمین نمودهایم که مطابق با سازههای ساختمانی و استاندارد برق مصر (نسخه تطبیقیافته IEC 60364) میباشد.

- استانداردسازی انتخاب کابل: کابلها بر اساس منطقه دستهبندی شدهاند (RVV3 ×2.5mm ² برای چراغهای دیواری، RVV3 ×1.5mm ² برای چراغهای کفی)، که در آن کابلهای ضد آب و محافظتشده بهصورت یکدست انتخاب شدهاند تا تحمل شرایط بیابانی مصر را داشته باشند.

- نصب لولهکشی یکپارچه: از مجاری آلیاژ آلومینیوم برای نمای خارجی، لولههای فولاد گالوانیزه برای نصبهای زیرزمینی و لولههای پنهان ساختار فولادی برای مناطق سقفی استفاده شده است، همه با عمق دفن یکسان ( ≥۵۰ سانتیمتر زیرزمین)، با فاصلهگذاری ثابت ( ≤1.5 متر) و استانداردهای آببندی ضدآب.

- ادغام جعبه توزیع: نصب یک جعبه توزیع برق ضدآب در فضای باز با رتبه IP65 (ساخته شده از فولاد ضدزنگ 304) همراه با محافظهای سورج داخلی (سازگار با ±نوسانات ولتاژ 15%) و دستگاههای جریان باقیمانده (RCD) (جریان عملکردی ≤30mA). رزرو کردن 20٪ مدارهای پشتیبان و اطمینان از اتصال یکپارچه به زمین (مقاومت ≤4ω ).

2.3.2 ادغام ایمنی و انطباق مدار

تمام طراحیهای مدار مطابق با استاندارد ولتاژ 220V/50Hz مصر بوده و شامل فناوریهای حفاظت در برابر اتصال کوتاه، حفاظت در برابر جریان نشتی و حفاظت در برابر صاعقه میشوند. گزارش آزمون انطباق الکتریکی ارائه شده است تا تأییدیه مقررات محلی به دست آید.

مرحله 4: ارائه توضیحات فنی و تأیید طرح

ما نقشههای ادغامشده، مشخصات فنی و اسناد طراحی لولهکشی/مدار را در قالب یک دفترچه جامع گردآوری خواهیم کرد و به مشتری ارائه توضیحات فنی دقیقی خواهیم داد تا موارد زیر را شفافسازی و تأیید نمایند:

- کاملبودن و دقت نقشهها و مدارک، همچنین انطباق نتایج با الزامات.

- نقاط عطف ساخت، چالشهای فنی و راهحلهای آن در هر مرحله؛

- اجرای الزامات انطباق محلی در مصر (گواهینامه GOEIC، مجوزهای ساخت و رعایت تعطیلات مذهبی);

- همکاری مورد نیاز مشتری و رویههای بعدی هماهنگی ساخت.

مرحله ۵: هماهنگی ساخت و کنترل فنی

ما پشتیبانی فنی جامع ارائه میدهیم، راهحلهای فنی را اجرا میکنیم و کنترل کیفیت ساخت را تضمین مینماییم.

- راهنمایی فنی در محل: نظارت بر نصب و کالیبرهکردن تجهیزات روشنایی، نصب لولهکشی، سیمکشی برق و عایقبندی ضد آب به منظور اطمینان از انطباق با مشخصات طراحی.

- عیبیابی و کنترل اثرات: در عیبیابی همزمان اثرات روشنایی بهطور کامل مشارکت میشود، با تمرکز بر کالیبرهکردن دقت رنگ پرچم مصر و اطمینان از اجرای روان اثرات پویا.

- کنترل کیفیت: بهطور منظم، صحت سازههای فولادی، پوششهای محافظ در برابر خوردگی و وضعیت آببندی کابلها را بررسی کنید و سازگاری آنها با محیط دارای دمای بالا و باد شن مصر را تضمین نمایید و گزارشهای کنترل فنی صادر کنید.

- اصلاح مشکلات: در مورد انحرافات فنی در حین اجرا، بلافاصله برنامه را بهینه کنید و اقدامات اصلاحی را هدایت نمایید تا اجرای پروژه مطابق با الزامات تضمین شود.

III. مشخصات فنی دقیق سیستم اصلی

3.1 طراحی سیستم روشنایی (سناریوی مصر)

3.1.1 سیستم روشنایی دیواری RGBW

- مشخصات محصول: مدل WL-RGBW-36W، 220V/50Hz AC، ردهبندی IP67، با پوسته آلیاژ آلومینیوم آندایز شده 6063 و شیشه مقاوم در برابر UV، دمای عملیاتی از -25 °C تا +60 °C، و حداقل پرداخت سطحی Ra ≥88.

- مشخصات نصب: پایههای آلیاژ آلومینیوم بهصورت خطی چیده شده (فاصلهگذاری ≤1.5m) با قابلیت تنظیم در محدوده 0-45 ° زاویهها، با اطمینان از روشنایی دیوار ≥200lx. کف صندوق کابل باید پنهان و درزگیر شده باشد.

- فناوری افکت: به طور دقیق سه رنگ پرچم مصر را بازتولید میکند —قرمز (#D81E05)، سفید (#FFFFFF) و مشکی (#000000) —با نوارهای عمودی ثابت (با حفظ تناسبهای پرچم) و افکتهای حرکتی متحرک، همگام با تجهیزات روشنایی دیگر.

3.1.2 سیستم چراغهای ستونی + چراغهای تعبیهشده در زمین + چراغهای فواره

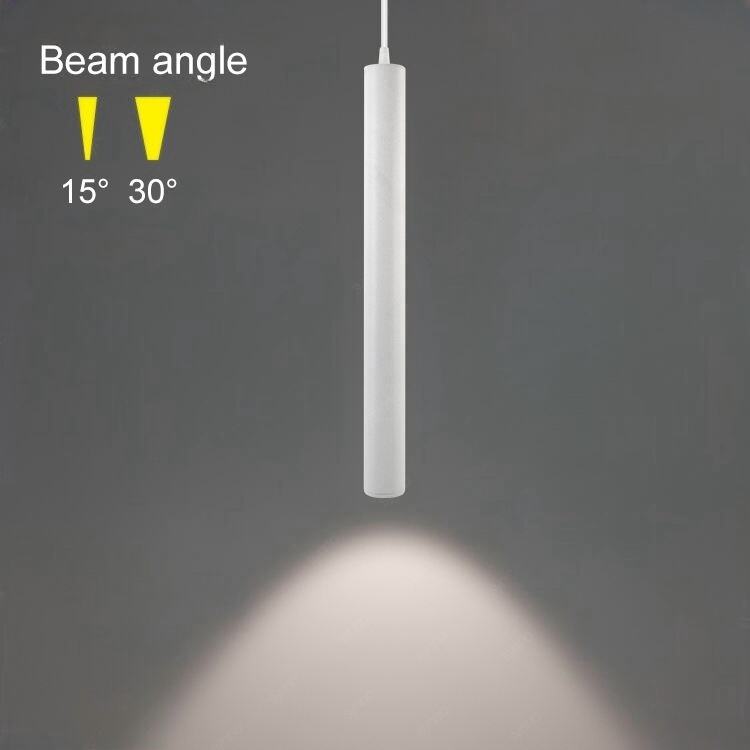

- چراغهای ستونی: لامپ رنگی RGBW 24 وات (زاویه پرتاب 30-45 ° درجه) با پوشش انعطافپذیر ستون (فاصله 15-20 سانتیمتری)، نصبشده روی پایههای فولاد ضدزنگ 304 با پوشش ضد زنگ و مقاوم در برابر خوردگی.

- نور زیرزمینی: مدل DL-RGBW-24W، رده IP67، صفحه شیشه مقواای (با حداقل مقاومت فشاری 200 کیلوگرم)، در یک چاله پیشنصبشده با استفاده از شن و بتن نصبشده، در موقعیتی حداقل 30 سانتیمتر بالاتر از لبه پیادهرو، با تمیزکاری ماهانه صفحه.

- چراغ فواره: ردهبندی ضد آب IP68، خروجی توان 18-24 وات، نصب شده در ارتفاع 5 تا 10 سانتیمتری از کف استخر، دارای درزگیر اختصاصی زیرآبی و روشنایی همزمان با الگوهای جریان آب.

3.1.3 سیستم روشنایی سقف BERMILLAN

- مشخصات: ارتفاع هر کاراکتر 4 تا 6 متر با ضخامت 30 تا 40 سانتیمتر، دارای پوسته فولاد ضدزنگ 304 سمبادهخورده و صفحه آکریلیک مقاوم در برابر UV وارداتی، با ردهبندی ضد آب IP65.

- روشنایی و کنترل: ماژولهای LED RGBW (12 وات در هر ست)، تولید نور سفید واقعی 6000 کلوین در روزهای عادی و اثرات پویای تمامرنگ در مناسبتهای جشنی، یکپارچهشده با سیستم کنترل جهانی.

- سازه فولادی: شیار فولادی 8 میلیمتری (استاندارد ES 2629)، مجهز به قابهای مستقل و محکمشده با پیچهای شیمیایی. با استحکام کششی ≥15 کیلونیوتن و مقاومت در برابر باد ≥15 متر/ثانیه، سیستم دارای پوشش اپوکسی پایه و روکش فلورکربن برای محافظت در برابر خوردگی.

3.2 راهحل یکپارچهسازی مدار لولهکشی و سیستم کنترل

3.2.1 طراحی یکپارچه لولهکشی و مدار

برنامهریزی یکنواخت بر اساس منطقه به منظور تضمین کابلکشی پنهان، ایمن و مقاوم در برابر شرایط آب و هوایی.

- نمای خارجی: کابل نورپردازی دیواری از طریق یک محفظه آلیاژ آلومینیوم عبور میکند و به صورت پنهان در امتداد خط کمر و سقف قرار میگیرد، با آببندی کامل محفظه و دیوار.

- زمین: کابلهای چراغهای دفنشده باید در لولههای فولادی گالوانیزه نصب شوند (عمق دفن ≥50 سانتیمتر)، همراه با نقاط دسترسی تعمیر و نگهداری در نظر گرفتهشده و دوری از خطوط شهری.

- سقف: کابلهای حروف روشنایی در امتداد فولاد کانال پنهان میشوند، با لولههای فولادی به فاصله ≤1.5 متر از یکدیگر جهت جلوگیری از فشردگی.

- منطقه فواره: کابل زیرآبی از لوله آببندی اختصاصی استفاده میکند و در لبه استخر به جعبه تقسیم ضدآب متصل میشود، با دو لایه آببندی در محل اتصال.

3.2.2 طرح اتصالات سیستم کنترل

با استفاده از نرمافزار کنترل حرفهای Madrix، امکان "روشنکردن با یک کلیک و همگامسازی در تمامی محدوده" فراهم میشود.

- ادغام سختافزار: کنترلر اصلی DMX512/Art-Net، ماژول کنترل منطقهای و جعبه توزیع ضدآب بیرونی با قابلیت ذخیره برنامه در حالت آفلاین، با پشتیبانی از تغییر دستی و خودکار.

- کنترل زمانبندیشده: حالت روز (روشن شدن نور سفید گرم) → صرفهجویی خودکار در انرژی در ساعت 23:00 → حالت تعطیلات (چراغهای رنگی پویا) → حالت ویژه (رنگهای پرچم ملی)، با تغییر دقیق بر اساس زمانبندی

- سیستم یکپارچه: چراغهای دیواری نورپردازی تمام رنگی در تمام مناطق را فراهم میکنند و بهصورت همزمان چراغهای ستونی، چراغهای تعبیهشده در دیوار، چراغهای فواره و نشانههای روشن را فعال میکنند —بدون تأخیر و بدون انحراف

چهارم. انطباق و تضمین کیفیت در مصر

4.1 اجرای الزامات انطباق

- انطباق محصول: تمام تجهیزات روشنایی و تجهیزات الکتریکی دارای گواهی CE و RoHS بوده و دارای تأییدیه GOEIC مصر هستند و مواد مورد استفاده مطابق با استانداردهای محلی میباشند.

- رعایت مقررات ساختوساز: از همزمانی با تعطیلات بزرگ اسلامی (عید الفطر و عید الاضحی) پرهیز شود و نصب ساختمان و صدور مجوزهای تأمین برق بهموقع انجام گیرد.

- رعایt مقررات فرهنگی: افکتهای روشنایی و نمایش رنگها با فرهنگ اسلامی سازگار باشند، شامل عناصر حساس نباشند و رنگهای پرچم ملی را بهدرستی و مناسب نمایش دهند.

4.2 اقدامات تضمین کیفیت

- تضمین مواد: ساختهشده از فولاد ضدزنگ 304، آلیاژ آلومینیوم 6063 و آکریلیک مقاوم در برابر UV، طراحیشده برای شرایط گرم و شنی مصر با عمر مفیدی بیش از 50,000 ساعت.

- اقدامات ایمنی ساختوساز: آزمون کششی سازه فلزی، بازرسی درزگیری ضدآب و آزمون پیوستگی مدار، همراه با صدور گزارش آزمون برای هر یک از این مراحل.

- نگهداری و پشتیبانی: برنامههای تمیزکاری ماهانه و بازرسی فصلی در نظر گرفته شده، مسیرهای دسترسی نگهداری پیشبینیشده، قطعات یدکی در دسترس و پشتیبانی از شبکه خدمات خارج از کشور فراهم است.

V. فهرست تحویلیها

پس از تکمیل پروژه، مجموعهای از خروجیها را در قالبهای Word و PDF به منظور بایگانی و پذیرش توسط مشتری ارائه خواهیم داد.

- بخش ۱: اسناد اصلی و پروندههای ثبت (مشتری نسخههایی از مواد و «فرم تأیید دریافت مواد» را ارائه میدهد);

- بخش ۲: نقشههای یکپارچه و بهینهسازی شده (مجموعه کامل در فرمتهای CAD.dwg و PDF، شامل تصاویر سهبعدی);

- بخش III: اسناد اجرای فنی (راهنمای اجرا مرحلهبهمرحله، طرح یکپارچهسازی روشنایی/لولهکشی/کنترل);

- بخش IV: مدارک انطباق و بازرسی (گواهی معتبر محصول، گواهی دسترسی به بازار مصر، گزارش بازرسی ساخت);

- بخش ۵: راهنمای بهرهبرداری و نگهداری (شامل راهنمای عملیات سیستم کنترل، رویههای نگهداری روزانه و راهحلهای عیبیابی).

موارد کاربرد: پروژههای بزرگمقیاس در منطقه مرکزی تجاری (CBD)، محیطهای اداری و پروژههای خارج از کشور (مصر)

مولفههای اصلی شامل: سیستمهای طراحی با CAD، سیستمهای نورپردازی RGB، صفحهنمایش بیرونی، نمایشگرهای روشن شده سقفی و سیستمهای پروژکسیون سهبعدی است.

استانداردهای سازگاری: مطابق با مشخصات بینالمللی نصب مهندسی، سازگار با ولتاژ محلی مصر (220V/50Hz)، شرایط آبوهوایی و الزامات فرهنگی.

1. سیستم طراحی CAD (پروژه نورپردازی RGB برای سایبان سقفی بلند)

1.1 فهرست کارها و الزامات اصلی

|

نوع ترسیم |

محتوای اصلی حاشیهنویسی |

نکات کلیدی سازگاری با تجارت خارجی |

|

چیدمان نقشه (ایکنوگرافی) |

ابعاد سایبان باران، نقاط نصب نورپرداز RGB (فاصلهگذاری و فاصله از لبه)، مسیر کابلکشی و محل جعبه کنترل |

برچسبگذاری دوگانه (متریک: mm/m؛ اینچی: inch/ft) همراه با مرجع واضح مختصات نقطه |

|

نمای عمودی |

ارتفاع سایبان، ارتفاع نصب فانوس، زاویه پرتاب پرتو و یکپارچهسازی با نمای معماری |

دامنه پوشش پویای پرتو را علامتگذاری کنید و آن را با سبک دکوراسیون دیوار پردهای هماهنگ نمایید |

|

تصویر دیوار پردهای |

مصالح دیوار پردهای، روش نصب فانوسها و اتصال به دیوار پردهای، درزهای آببندی، اندازه سوراخها |

شماره استاندارد بینالمللی ماده را مشخص کنید (به عنوان مثال، ASTM A240 برای فولاد ضدزنگ 304) |

|

نقشه جزئیات نصب (مهم) |

1. نصب قفسهنور (تعبیهشده/روکار): ابعاد پایه، مشخصات پیچ، جزئیات اتصال به سازه؛ 2. اتصالات دیوار پردهای: نوع چسبآببند، یادداشتهای تأیید تحمل بار؛ 3. نصب سیمکشی: مسیر لولهکشی، مسیرهای پیشبسته، جعبههای تقسیم آببند؛ 4. جعبه کنترل: روش نصب، تمهیدات در برابر باران و گردوغبار |

نقشه جزئیات گره شامل توصیف مقاومت مواد در برابر شرایط آبوهوایی است و برای محیط گرم و شنی مصر طراحی شده است. |

1.2 استانداردهای ترسیم

- در اوتوکد 2018 یا نسخههای بعدی ترسیم کنید، به صورت .dwg ذخیره کنید و نسخه PDF آن را برای بازبینی توسط مشتری ارائه دهید.

- ضخامت خط زیرلایه: خطوط ساختار اصلی 0.3 میلیمتر، خطوط حاشیهنویسی 0.15 میلیمتر، ترسیمات جزئیات گره در مقیاس ≥1:20.

- نمایش اثرات پویا برای تیرهای اضافی، با مشخص کردن مناطق پوشش و مسیرهای حرکتی اثراتی مانند اسکن و گرادیان.

- بخش امضا شامل فضاهای مشخصشده برای طراحی، بازبینی و تأیید است، همراه با فضای در نظر گرفتهشده برای تأییدیه مشتری.

2. سیستم نورپردازی RGB برای سایبانهای با ارتفاع زیاد (نصب، کنترل و بهرهوری انرژی)

2.1 طرح ساخت و نصب

2.1.1 نصب روشنایی

- نوع تعبیهشده: هنگام ساخت پیشساخته سایبان، سوراخهایی با قطری 2 تا 5 میلیمتر بزرگتر از قطر خارجی چراغ در نظر گرفته میشود. پس از نصب، از واشر سیلیکونی خنثی مقاوم در برابر عوامل جوی (مطابق ISO 11600) برای پُر کردن شکافها و ایجاد عایق دوم ضد آب استفاده میشود.

- نوع نصب سطحی: پایهی سفارشی از فولاد ضدزنگ 304 که از طریق بولت به سازه سایبان متصل میشود (جوشهای جوش با رنگ ضد زنگ و روکش فلورکربن پوشانده شدهاند) و ظرفیت باربری آن حداقل سه برابر وزن چراغ است.

2.1.2 ساخت خط

- انتخاب کابل: از کابل RVV3 ×1.5mm ² کابل ضدآب (IP67) برای خطوط برق و جفت آبخور شیلددار RVSP2 ×0.75mm ² (ضد تداخل) برای خطوط سیگنال استفاده شود. کابلهای مذکور باید در لولههای فولاد گالوانیزه (برای استفاده در فضای باز) یا لولههای PVC (برای استفاده در فضای داخلی) نصب شوند.

- شرایط پیشنصب: تمام سیمکشیهای داخلی باید همراه با سازه درجا نصب شوند تا از آسیب سازهای جلوگیری شود. از جعبههای تقسیم ضدآب در فضای باز (با رتبه IP65) استفاده شود و نقاط اتصال با نوار عایق آببندی و نوار عایق دو لایه پیچانده شوند.

- روش عیبیابی: آزمایش روشنایی و یکنواختی رنگ برای هر چراغ → عیبیابی اثرات پویا → ثبت پارامترهای عملیاتی → تولید گزارش عیبیابی.

2.1.3 نصب روشنایی خارجی تجاری (تمرکز اصلی)

2.1.3.1 نصب چراغهای فواره

- انتخاب لامپ: انتخاب چراغ فواره آبی مقاوم در برابر آب با قابلیت RGBW و رتبه IP68، با توان 18 تا 24 وات، که برای عمق آب 0.5 تا 1.5 متر طراحی شده و دارای افکتهای نورپردازی پویا همگام با الگوهای پاشش آب است.

- روش نصب: در داخل کف استخر فواره به صورت توکار، با استفاده از پایههای نگهدارنده از جنس فولاد ضدزنگ که به قطعات پیشسازی شده جوش داده شدهاند. ارتفاع پایه باید 5 تا 10 سانتیمتر بالاتر از لایه رسوبی استخر باشد تا از مسدود شدن نور جلوگیری شود.

- آببندی: کابل از طریق اتصالدهنده آببندی اختصاصی زیرآبی عبور کرده، از لولهکشی عبور میکند و به جعبه تقسیم آببند در لبه استخر متصل میشود و در محل اتصال با آببند تخصصی زیرآبی تقویت میشود تا در طول غوطهوری طولانیمدت هیچ گونه نشتی رخ ندهد.

2.1.3.2 نصب روشنایی ستون (اسپات لایت + چراغهای ستونی با پایه)

- چراغ ریز 24 وات RGBW: دو تا چهار عدد از این چراغها را در امتداد محیط پایه هر ستون نصب کنید، بهگونهای که فاصله آنها با توجه به قطر ستون تنظیم شود (دو عدد برای ستونهای 50 سانتیمتری و چهار عدد برای ستونهای بالای 50 سانتیمتر). پرتوهای نور را در محدوده 30 تا 45 درجه تنظیم کنید تا روشنایی یکنواخت حاصل شود. چراغها را با استفاده از بستهای فولاد ضدزنگ و پوشش ضدخوردگی به زمین یا پایه ستون محکم کنید و با پیچهای انبساطی به زمین ثابت نمایید. ≤50 سانتیمتر، 4 دستگاه برای >50 سانتیمتر). پرتو 30 تا 45 ° درجه را تنظیم کنید تا روشنایی یکنواخت حاصل شود. چراغها را با استفاده از بستهای فولاد ضدزنگ و پوشش ضدخوردگی به زمین یا پایه ستون محکم کنید و با پیچهای انبساطی به زمین ثابت نمایید.

- چراغهای نصبشده روی ستون: از چراغهای انعطافپذیر RGBW که به دور بدنه ستون پیچیده میشوند استفاده شود، با فاصله 15 تا 20 سانتیمتری از یکدیگر و دو سر آنها با کلیپسهای فولاد ضدزنگ ثابت گردد (کلیپسها دارای پدهای نرم ضدلغزش هستند تا از خراشیدگی سطح جلوگیری شود). نقاط اتصال چراغها ضدآب شده و کابلها بهصورت پنهان در امتداد ستون به جعبه اتصالات پایه هدایت میشوند تا اثری مکمل با پرتوهای فلودلایت ایجاد شود.

2.1.3.3 نصب چراغهای دیواری RGBW (پروژه ویژه، قبلاً با نام روشنایی نرگس شناخته میشد)

2.1.3.3.1 محصولات پیشنهادی و پارامترهای اصلی

- محصول اصلی: شستدهنده دیواری RGBW ضدآب برای فضای باز (مدل: WL-RGBW-36W، مناسب برای روشنایی نمای مصری). این محصول با توان خروجی 36 وات و ورودی AC220V/50Hz، قابلیت کنترل DMX512 را دارد و بهراحتی با سیستم کنترل پروژه ادغام میشود تا نورپردازی یکنواخت دیوار را فراهم کند.

- مشخصات کلیدی: درجه حفاظت IP67 در برابر آب، زاویه روشنایی ° 120 درجه (بدون ایجاد گوشههای تاریک روی دیوار)، شاخص بازتاب رنگ Ra ≥88، محدوده دمای رنگ از 2700 کلوین (سفید گرم) تا 6000 کلوین (سفید واقعی)، نور ترکیبی چهاررنگ RGBW؛ بدنه از آلیاژ آلومینیوم آندایز شده 6063 ساخته شده و پوشش عبور نور از شیشه سکور مقاوم در برابر UV است. دمای کاری: -25 تا +50 درجه سانتیگراد، مناسب برای آبوهوای گرم و باد شنی مصر. قابلیت بازتولید دقیق رنگ را دارد و میتواند به صورت استاتیک یا پویا سه رنگ پرچم مصر (قرمز، سفید و مشکی) را نمایش دهد. °C تا +60 °C, suitable for Egypt's high-temperature sandy climate. Supports precise color reproduction, capable of static display and dynamic switching of the Egyptian flag's three colors (red, white, and black).

- الزامات گواهینامه: دارا بودن گواهیهای بینالمللی CE و RoHS، همراه با تأییدیه محصول GOEIC مصر، جهت اطمینان از انطباق با مقررات گمرکی و پذیرش محلی.

2.1.3.3.2 روش نصب

- نصب ثابت: پشتیبانهای آلیاژ آلومینیوم باید بهصورت خطی در امتداد بالا، پایین یا خط کمر نمای ساختمان قرار گیرند و با فاصله نصب ≤1.5 متر، پس از همپوشانی نور، روشنایی یکنواخت دیوار ( ≥200lx) را تضمین کنند. پشتیبانها باید با استفاده از پیچهای انبساطی یا مهرههای شیمیایی به سازه ساختمان متصل شوند و واشرهای ضد لغزش در سطوح تماس اضافه شوند تا از خراشیدگی سطوح جلوگیری شود.

- زاویه قابل تنظیم: زاویه پرتاب چراغ بین 0 تا 45 °است و قابل تنظیم بر اساس ارتفاع دیوار است (برای دیوارهای ° 5 متر به 20 ≤و برای دیوارهای بیش از 5 متر به 30 ° درجه) تا پوشش کامل بدون نقاط کور تضمین شود.

- نصب کابل: خطوط برق باید از کابلهای RVV3 استفاده کنند ×2.5mm ² کابلهای ضد آب، در حالی که خطوط سیگنال باید از جفت به هم تابیده شده با محافظ RVSP2 استفاده کنند ×0.75mm ² . کابلها باید در مجاری آلومینیومی (با فاصلهگذاری ثابت ≤1 متر) پنهان شوند و شکافهای بین مجاری و دیوارها با آببند سیلیکونی مقاوم در برابر عوامل جوی درزگیری شوند. تمام اتصالات کابل باید در جعبههای تقسیم ضد آب (درجه IP65) قرار گیرند و با نوار ضد آب پوشانده شوند.

2.1.3.3.3 برنامه اجرایی برای اثربخشی

- روشنایی گرم خارجی (حالت روز): روی نور سفید گرم (2700K-3000K) تنظیم شود، با دیوارنشانها که روشنایی کمی را در فضا حفظ میکنند. روشنایی یکنواخت، فضایی گرم و ظریف تجاری ایجاد میکند و با درخشش گرم نورهای ستونی و تعبیهشده هماهنگی دارد.

- اثرات رنگی پویا RGB (حالت جشنواره): دارای اثرات تدریجی، تعقیب و جارو برقی. چراغهای وال واش به صورت هم زمان در سراسر دیوار کار میکنند و امکان چرخش رنگ و ایجاد بازی سه بعدی با نورهای فواره و حروف روشنایی را فراهم میآورند.

- اثرات رنگی پرچم مصر (حالت ویژه): نرمافزار به طور دقیق رنگهای قرمز، سفید و سیاه پرچم مصر را بازتولید میکند و دو فرمت نمایش را پشتیبانی میکند: نمایش ثابت (نوارهای عمودی رنگی که با تناسبات پرچم همراه است) و نمایش پویا (گذارهای رنگی متوالی در سراسر دیوار). این حالت برای جشنهای بزرگ محلی یا مناسبتها ایدهآل است.

2.1.3.3.4 دستورالعملهای نصب و استفاده

- سازگاری با محیط: مصر دارای توفانهای مکرر شن است. قبل از نصب، ناخالصیها را از منطقه نصب بردارید. پس از نصب، هر ماه یک بار روکش عبور نور را تمیز کنید. از قرار گرفتن مستقیم چراغ در معرض نور شدید خورشید خودداری کنید. میتوانید از سایهبان استفاده کنید تا از کاهش شدت نور جلوگیری شود.

- مشخصات ساخت: مطابق با استاندارد برق ولتاژ پایین مصر (نسخه تطبیقیافته IEC 60364)، همراه با مقاومت اتصال به زمین ≤4ω و نصب دستگاههای جریان باقیمانده (RCD) (جریان قطع ≤30mA). برنامهریزی ساخت را خارج از تعطیلات مذهبی انجام دهید و مجوزهای ساخت نمای ساختمان را بهموقع اخذ کنید.

- تنظیمات پس از نصب: پس از نصب، روشنایی و یکنواختی رنگ هر چراغ را آزمایش کنید، سپس تنظیمات پیوند جامع را انجام دهید، با تمرکز بر کالیبره دقیق رنگهای پرچم مصر بهمنظور اطمینان از نمایش یکنواخت و بدون خطا در تمام دیوار. پارامترهای تنظیمات را ثبت کرده و گزارش تخصصی تنظیمات را تهیه کنید.

- دسترسی خدماترسانی: تجهیزات روشنایی با ساختاری جداشونده طراحی شدهاند و دسترسی خدماترسانی را فراهم میکنند تا تعویض ماژولها و تمیزکاری در آینده آسان شود. کانال کابلکشی دارای دربهای خدماترسانی ذخیرهشده است تا تعمیر و نگهداری سیمکشی تسهیل گردد.

2.1.3.4 نصب چراغهای زیرزمینی RGBW 24 وات (پروژه ویژه)

2.1.3.4.1 محصولات پیشنهادی و پارامترهای اصلی

- محصول اصلی: چراغ زمینی مقاوم در برابر آب و هوای باز با قابلیت RGBW (مدل: DL-RGBW-24W، مناسب برای صادرات و بازار مصر). دارای توان خروجی 24 وات، ولتاژ ورودی AC220V/50Hz (سازگار مستقیم با برق شهری مصر)، قابلیت کنترل DMX512 و سازگاری کامل با سیستم کنترل یکپارچه پروژه.

- مشخصات کلیدی: حفاظت رده IP67 (ضد گرد و غبار و ضد آب، تحملکننده طوفانهای شن مصر و تجمع موقت آب); زاویه تابش قابل تنظیم (15-60 °); شاخص بازتاب رنگ (Ra) ≥85؛ محدوده دمای رنگ (سفید گرم: 2700K تا سفید سرد: 6000K); نور ترکیبی چهار رنگ RGBW؛ سوئیچ دو حالته (روز/شب/تعطیلات); پوسته فولاد ضدزنگ 304 با پرداخت مات؛ صفحه شیشه مقوا (ضد انعکاس، مقاوم در برابر فشار ≥200kg); دمای کاری -20 ℃ تا +60 ℃; مناسب برای آب و هوای گرم مصر.

- الزامات گواهینامه: دارا بودن گواهیهای بینالمللی CE و RoHS، همراه با تأییدیه محصول GOEIC مصر، جهت اطمینان از انطباق با مقررات گمرکی و پذیرش محلی.

2.1.3.4.2 روش نصب

- نصب از پیش تعبیهشده: ابتدا یک چاله تعبیهشده (به قطر 10 تا 15 سانتیمتر بزرگتر از قطر خارجی چراغ و عمقی حداقل 10 سانتیمتر بیشتر از ارتفاع چراغ) حفر کنید. لایه پایهای به ضخامت 10 سانتیمتر از شن و ماسه برای زهکشی و مقاومت در برابر آب قرار دهید، سپس یک لایه بتنی 5 سانتیمتری برای ثابتکردن چراغ ریختهگری کنید و اطمینان حاصل کنید که نصب چراغ در سطحی کاملاً افقی و پایدار انجام شود.

- ثابتکردن چراغ: پایهٔ چراغ را با استفاده از پیچهای منبسطشونده از جنس فولاد ضدزنگ به فونداسیون بتنی محکم کنید. شکاف بین پایه و زمین را با چسب سیلیکونی خنثی مقاوم در برابر آب و هوا درزگیری کنید (تا از نفوذ آب باران و گرد و غبار جلوگیری شود). چراغ را در فاصلهای از مسیرهای اصلی پرتردد نصب کنید و حداقل فاصلهٔ ≥۳۰ سانتیمتری از لبهٔ کنارهٔ خیابان را رعایت کنید. فاصلهٔ بین چراغها باید بر اساس نیازهای روشنایی تعیین شود (معمولاً هر ۲ تا ۳ متر یک دستگاه بهمنظور ایجاد نوار نوری یکنواخت).

- نصب کابل: از کابلهای ضدآب RVV3 ×1.5mm ² کابلهای ضدآب (IP67) برای سیمکشی و کابلهای جفت آبشاری شیلددار (RVSP2 ×0.75mm ² ) برای خطوط سیگنال. کابلها را در لولههای فولادی گالوانیزه به صورت زیرزمینی (دفن شده حداقل به عمق 50 سانتیمتر برای جلوگیری از آسیب ناشی از ترافیک) مدفون کنید و آنها را در جعبههای تقسیم ضد آب (IP65) متصل نمایید. از پوشش ضد آب روی کابلها استفاده کنید و در جعبههای تقسیم، دهانههای دسترسی برای تعمیرات آینده فراهم کنید.

2.1.3.4.3 دستورالعملهای نصب و استفاده

- سازگاری با محیط: مصر مرتباً با توفانهای شن مواجه است. قبل از نصب، ناخالصیها را از چاله از پیش دفن شده خارج کنید. پس از نصب، گرد و غبار روی صفحه را به طور دورهای تمیز کنید (یک بار در ماه). از نصب در مناطق پست یا مناطق مستعد غرقاب شدن خودداری کنید. در صورتی که محل مستعد تجمع آب باشد، باید لولههای زهکشی اضافی نصب شوند تا از غوطهوری طولانیمدت تجهیزات جلوگیری شود.

- مشخصات ساخت: مطابق با استاندارد برق ولتاژ پایین مصر (نسخه تعدیل شده IEC 60364)، با مقاومت اتصال به زمین ≤4ω و نصب دستگاه قطع باقیمانده (RCD) (جریان قطع ≤30mA). برنامهریزی ساخت و ساز را خارج از تعطیلات مذهبی انجام دهید، قبل از بازرسی لولهکشی زیرزمینی مجوز لازم را دریافت کنید و از آسیب به لولههای شهرداری خودداری نمایید.

- حفاظت ایمنی: باید علائم هشدار به صفحات شیشه مقوا (تمپرد) چسبانده شود تا از عبور پیاده و آسیب به آن جلوگیری شود؛ در نقاط ورودی کانال کابل باید عملیات مقاوم در برابر سایش انجام شود تا از خراشیدگی لایه عایق کابل ناشی از لبههای لوله فولادی جلوگیری گردد.

- راهاندازی و نگهداری: پس از نصب، تست تک تک چراغها را از نظر روشنایی و یکنواختی رنگ انجام دهید و اثرات هماهنگی با چراغهای سایبان، ستون و حروف روشن را راهاندازی کنید. کانالهای دسترسی برای تعمیر و نگهداری را در نظر بگیرید و چراغها را با ساختار جداشدنی طراحی کنید تا تعویض ماژولها و تمیزکاری در مراحل بعدی تسهیل شود.

2.1.3.1 نصب چراغهای فواره

- انتخاب لامپ: انتخاب چراغ فواره آبی مقاوم در برابر آب با قابلیت RGBW و رتبه IP68، با توان 18 تا 24 وات، که برای عمق آب 0.5 تا 1.5 متر طراحی شده و دارای افکتهای نورپردازی پویا همگام با الگوهای پاشش آب است.

- روش نصب: در داخل کف استخر فواره به صورت توکار، با استفاده از پایههای نگهدارنده از جنس فولاد ضدزنگ که به قطعات پیشسازی شده جوش داده شدهاند. ارتفاع پایه باید 5 تا 10 سانتیمتر بالاتر از لایه رسوبی استخر باشد تا از مسدود شدن نور جلوگیری شود.

- آببندی: کابل از طریق اتصالدهنده آببندی اختصاصی زیرآبی عبور کرده، از لولهکشی عبور میکند و به جعبه تقسیم آببند در لبه استخر متصل میشود و در محل اتصال با آببند تخصصی زیرآبی تقویت میشود تا در طول غوطهوری طولانیمدت هیچ گونه نشتی رخ ندهد.

2.1.3.2 نصب روشنایی ستون (اسپات لایت + چراغهای ستونی با پایه)

- چراغ ریز 24 وات RGBW: دو تا چهار عدد از این چراغها را در امتداد محیط پایه هر ستون نصب کنید، بهگونهای که فاصله آنها با توجه به قطر ستون تنظیم شود (دو عدد برای ستونهای 50 سانتیمتری و چهار عدد برای ستونهای بالای 50 سانتیمتر). پرتوهای نور را در محدوده 30 تا 45 درجه تنظیم کنید تا روشنایی یکنواخت حاصل شود. چراغها را با استفاده از بستهای فولاد ضدزنگ و پوشش ضدخوردگی به زمین یا پایه ستون محکم کنید و با پیچهای انبساطی به زمین ثابت نمایید. ≤50 سانتیمتر، 4 دستگاه برای >50 سانتیمتر). پرتو 30 تا 45 ° درجه را تنظیم کنید تا روشنایی یکنواخت حاصل شود. چراغها را با استفاده از بستهای فولاد ضدزنگ و پوشش ضدخوردگی به زمین یا پایه ستون محکم کنید و با پیچهای انبساطی به زمین ثابت نمایید.

- چراغهای نصبشده روی ستون: از چراغهای انعطافپذیر RGBW که به دور بدنه ستون پیچیده میشوند استفاده شود، با فاصله 15 تا 20 سانتیمتری از یکدیگر و دو سر آنها با کلیپسهای فولاد ضدزنگ ثابت گردد (کلیپسها دارای پدهای نرم ضدلغزش هستند تا از خراشیدگی سطح جلوگیری شود). نقاط اتصال چراغها ضدآب شده و کابلها بهصورت پنهان در امتداد ستون به جعبه اتصالات پایه هدایت میشوند تا اثری مکمل با پرتوهای فلودلایت ایجاد شود.

2.1.3.3 نصب چراغهای زیرزمینی 24 وات RGBW (پروژه ویژه)

2.1.3.3.1 محصولات پیشنهادی و پارامترهای اصلی

- محصول اصلی: چراغ زمینی مقاوم در برابر آب و هوای باز با قابلیت RGBW (مدل: DL-RGBW-24W، مناسب برای صادرات و بازار مصر). دارای توان خروجی 24 وات، ولتاژ ورودی AC220V/50Hz (سازگار مستقیم با برق شهری مصر)، قابلیت کنترل DMX512 و سازگاری کامل با سیستم کنترل یکپارچه پروژه.

- مشخصات کلیدی: حفاظت رده IP67 (ضد گرد و غبار و ضد آب، تحملکننده طوفانهای شن مصر و تجمع موقت آب); زاویه تابش قابل تنظیم (15-60 °); شاخص بازتاب رنگ (Ra) ≥85؛ محدوده دمای رنگ (سفید گرم: 2700K تا سفید سرد: 6000K); نور ترکیبی چهار رنگ RGBW؛ سوئیچ دو حالته (روز/شب/تعطیلات); پوسته فولاد ضدزنگ 304 با پرداخت مات؛ صفحه شیشه مقوا (ضد انعکاس، مقاوم در برابر فشار ≥200kg); دمای کاری -20 ℃ تا +60 ℃; مناسب برای آب و هوای گرم مصر.

- الزامات گواهینامه: دارا بودن گواهیهای بینالمللی CE و RoHS، همراه با تأییدیه محصول GOEIC مصر، جهت اطمینان از انطباق با مقررات گمرکی و پذیرش محلی.

2.1.3.3.2 روش نصب

- نصب از پیش تعبیهشده: ابتدا یک چاله تعبیهشده (به قطر 10 تا 15 سانتیمتر بزرگتر از قطر خارجی چراغ و عمقی حداقل 10 سانتیمتر بیشتر از ارتفاع چراغ) حفر کنید. لایه پایهای به ضخامت 10 سانتیمتر از شن و ماسه برای زهکشی و مقاومت در برابر آب قرار دهید، سپس یک لایه بتنی 5 سانتیمتری برای ثابتکردن چراغ ریختهگری کنید و اطمینان حاصل کنید که نصب چراغ در سطحی کاملاً افقی و پایدار انجام شود.

- ثابتکردن چراغ: پایهٔ چراغ را با استفاده از پیچهای منبسطشونده از جنس فولاد ضدزنگ به فونداسیون بتنی محکم کنید. شکاف بین پایه و زمین را با چسب سیلیکونی خنثی مقاوم در برابر آب و هوا درزگیری کنید (تا از نفوذ آب باران و گرد و غبار جلوگیری شود). چراغ را در فاصلهای از مسیرهای اصلی پرتردد نصب کنید و حداقل فاصلهٔ ≥۳۰ سانتیمتری از لبهٔ کنارهٔ خیابان را رعایت کنید. فاصلهٔ بین چراغها باید بر اساس نیازهای روشنایی تعیین شود (معمولاً هر ۲ تا ۳ متر یک دستگاه بهمنظور ایجاد نوار نوری یکنواخت).

- نصب کابل: از کابلهای ضدآب RVV3 ×1.5mm ² کابلهای ضدآب (IP67) برای سیمکشی و کابلهای جفت آبشاری شیلددار (RVSP2 ×0.75mm ² ) برای خطوط سیگنال. کابلها را در لولههای فولادی گالوانیزه به صورت زیرزمینی (دفن شده حداقل به عمق 50 سانتیمتر برای جلوگیری از آسیب ناشی از ترافیک) مدفون کنید و آنها را در جعبههای تقسیم ضد آب (IP65) متصل نمایید. از پوشش ضد آب روی کابلها استفاده کنید و در جعبههای تقسیم، دهانههای دسترسی برای تعمیرات آینده فراهم کنید.

2.1.3.3.3 دستورالعملهای نصب و استفاده

- سازگاری با محیط: مصر مرتباً با توفانهای شن مواجه است. قبل از نصب، ناخالصیها را از چاله از پیش دفن شده خارج کنید. پس از نصب، گرد و غبار روی صفحه را به طور دورهای تمیز کنید (یک بار در ماه). از نصب در مناطق پست یا مناطق مستعد غرقاب شدن خودداری کنید. در صورتی که محل مستعد تجمع آب باشد، باید لولههای زهکشی اضافی نصب شوند تا از غوطهوری طولانیمدت تجهیزات جلوگیری شود.

- مشخصات ساخت: مطابق با استاندارد برق ولتاژ پایین مصر (نسخه تعدیل شده IEC 60364)، با مقاومت اتصال به زمین ≤4ω و نصب دستگاه قطع باقیمانده (RCD) (جریان قطع ≤30mA). برنامهریزی ساخت و ساز را خارج از تعطیلات مذهبی انجام دهید، قبل از بازرسی لولهکشی زیرزمینی مجوز لازم را دریافت کنید و از آسیب به لولههای شهرداری خودداری نمایید.

- حفاظت ایمنی: باید علائم هشدار به صفحات شیشه مقوا (تمپرد) چسبانده شود تا از عبور پیاده و آسیب به آن جلوگیری شود؛ در نقاط ورودی کانال کابل باید عملیات مقاوم در برابر سایش انجام شود تا از خراشیدگی لایه عایق کابل ناشی از لبههای لوله فولادی جلوگیری گردد.

- راهاندازی و نگهداری: پس از نصب، تست تک تک چراغها را از نظر روشنایی و یکنواختی رنگ انجام دهید و اثرات هماهنگی با چراغهای سایبان، ستون و حروف روشن را راهاندازی کنید. کانالهای دسترسی برای تعمیر و نگهداری را در نظر بگیرید و چراغها را با ساختار جداشدنی طراحی کنید تا تعویض ماژولها و تمیزکاری در مراحل بعدی تسهیل شود.

2.2 اثرات پویا و روشهای پخش

2.2.1 انواع اثرات اصلی

از اثرات پویا مانند اسکن، گرادیان، تعقیب، جهش و همگامسازی با موسیقی پشتیبانی میکند. برای تأمین الزامات مراکز تجاری، سه حالت پیشفرض پایه در دسترس است: چراغهای سقفی (کانوپی)، نورپردازی فوارهها، ستونها، نورهای دیواری (وال واشر) و چراغهای کفی که بهصورت همگام کنترل میشوند.

- حالت روز: سیستم از نورپردازی با تم گرم (2700K-3000K) استفاده میکند و چراغهای پخشکننده با شدت پایین بهطور مداوم روی کانوپی روشن هستند. نورهای ستون و پایه، نور سفید گرم تابش میکنند و با نور ملایم فوارهها بهصورت همگام عمل میکنند. وال واشرهای RGBW نور یکنواخت سفید گرمی را در سراسر دیوارها فراهم میکنند، در حالی که چراغهای تعبیهشده در کف، نور مکمل گرمی ارائه میدهند. این ترکیب، فضایی تجاری ظریف و باوقار ایجاد میکند که کاملاً برای عملیات روزمره مناسب است.

- حالت جشن: دارای افکتهای پویای تمام رنگ با عملکرد همگامشده چراغهای نقطهای سایبان، نورهای فواره، چراغهای ستونی و چراغهای تعبیهشده در کف. شستشوی دیواری چرخههای رنگی پویای RGB (گرادیان، دنبالهروی و غیره) را روی تمام دیوارها ایجاد میکند، در حالی که نورهای احاطهکننده ستونها و چراغهای پراکنده اثرات رنگی سهبعدی تشکیل میدهند. نورهای فواره همراه با نوسانات ستون آب تغییر رنگ میدهند. این سیستم از دنبالههای نوری قابل تنظیم برای مناسبتهای جشن تعطیلات پشتیبانی میکند و پس از ساعت 23:00 بهطور خودکار به حالت روزانه کممصرف تغییر میکند.

- حالت ویژه پرچم مصر: نرمافزار کنترل بهدقت رنگهای قرمز، سفید و سیاه پرچم مصر را بازتولید میکند، بهگونهای که نورهای شستشوی دیواری رنگهای پرچم را بهصورت نوارهای عمودی ثابت یا افکتهای در حال جریان روی تمام دیوارها هماهنگ میکنند. سایر چراغها بهطور خودکار به نور سفید گرم تغییر میکنند تا فضای مکان بهبود یابد. این حالت برای جشنهای بزرگ محلی و مناسبتها ایدهآل است و مربوطبودن فرهنگی منطقه را برجسته میکند.

- حالت روزانه: فضا از نورپردازی با دمای گرم (3000 کلوین) و چراغهای پراکنده کمشدت که همواره روشن هستند، استفاده میکند. چراغهای ستونها و پایهها نور سفید گرم تابش میدهند و نورهای فواره به صورت هماهنگ برای ایجاد فضایی آرامشبخش عمل میکنند. این طراحی فضایی با شکوه و تجاری مناسب برای عملیات روزمره ایجاد میکند.

- حالت جشن: به اثرات رنگی پویا تغییر میکند و چراغهای سقف، نورهای فواره و چراغهای ستونها به صورت هماهنگ کار میکنند. این حالت شامل گرادیان رنگی، الگوی حرکتی هماهنگ و اثرات نورپردازی سهبعدی ایجاد شده توسط چراغهای اجاقی و نورهای پراکنده است. نورهای فواره همراه با جریان آب تغییر رنگ میدهند. امکان تنظیم دنبالههای نوری خاص برای مناسبتهای جشن وجود دارد. پس از ساعت 23:00 بهطور خودکار به حالت روزانه تغییر میکند تا مصرف انرژی کاهش یابد.

2.2.2 منطق کنترل پخش

سیستم از تعویض زمانبندیشده (با دقت سطح دقیقه) از طریق دنبالههای اثر از پیش تنظیمشده در نرمافزار کنترل پشتیبانی میکند. کنترلر اصلی بیش از ۱۰ برنامه قابل شخصیسازی را به صورت آفلاین ذخیره میکند و نیاز به اتصال طولانیمدت به کامپیوتر را حذف میکند. برای نمای خارجی، یک تابع جدید کنترل منطقهای معرفی شده است که امکان عملکرد مستقل چراغهای فواره، ستونها یا هماهنگی کامل تمام مجموعه را فراهم میکند تا به نیازهای متنوع صحنه پاسخ دهد.

طراحی سیستم کنترل 2.3

|

روش کنترل |

پارامتر فنی |

صحنه قابل اعمال |

|

کنترل برنامهریزیشده (هسته) |

سیستم از یک سیستم کنترل DMX512/Art-Net با نرمافزار کنترل حرفهای (Madrix) استفاده میکند که امکان ویرایش برنامه، واردات/صادرات را فراهم میکند و دارای نمایشگر LCD روی کنترلر اصلی است. یک ماژول کنترل منطقهای جدید اضافه شده که کنترل نورپردازی مستقل یا همگام برای مناطقی مانند سایبانها، فوارهها و ستونها را ممکن میسازد و نیازهای نورپردازی همکارانه برای نمای خارجی را برآورده میکند. |

پروژههای بزرگمقیاس منطقه تجاری متمرکز و ایجاد فضای جشن و تعطیلات |

|

کنترل دستی |

پنل کنترل دارای یک دکمهی تغییر افکت و یک دستگیرهی تنظیم روشنایی برای عملکرد آسان است. |

عیبیابی موقت، کلید اضطراری |

|

کنترل هوشمند (اختیاری) |

اتصال به پلتفرم اینترنت اشیا، پشتیبانی از کنترل از راه دور از طریق اپلیکیشن موبایل و کنترل صوتی، مجهز به سنسور روشنایی (کاهش خودکار نور) |

فضای اداری لوکس، پردیس هوشمند |

۲.۴ طراحی صرفهجویی در انرژی و حفاظت از محیط زیست

- روشنایی با صرفهجویی انرژی: چراغهای الایدی RGB اسپات لایت با شار نوری ≥۱۲۰ لومن/وات و ضریب قدرت ≥۰٫۹ انتخاب شوند که بیش از ۶۰٪ صرفهجویی در مصرف انرژی نسبت به روشنایی سنتی فراهم میکنند و عمر مفیدی معادل ≥۵۰٬۰۰۰ ساعت دارند.

- حالت صرفهجویی در انرژی: روشن/خاموش شدن زمانبندیشده همراه با تنظیم خودکار روشنایی، قطع خودکار برق پس از ساعت 23

- بررسی اجمالی

- محصولات پیشنهادی