mall lighting, venue lighting, outdoor lighting, energy-saving lighting, lighting design, lighting construction, customized lighting, intelligent lighting, nightscape lighting, lighting renovation

lighting engineering, integrated lighting solution, LED lighting, road lighting, landscape lighting, building facade lighting, festival lighting, workshop lighting, cultural tourism lighting, illuminated signage

- Overview

- Recommended Products

- Architectural drawings: MALL facade construction drawings, roof structure drawings, curtain wall node drawings (with material specifications and thickness parameters), and canopy structure details (in DWG and PDF formats).

- Site layout plans: Outdoor master plan (including fountain locations, canopy column layouts, pedestrian walkways, and underground pipeline routing), and rooftop floor plan (specifying illuminated lettering installation zones and load-bearing points).

- Electrical foundation drawings: including original strong and weak current points in the building, distribution box locations with capacity specifications, and grounding system diagrams.

- Additional supplementary drawings: For any reserved lighting points or pre-buried pipelines, corresponding design drawings and on-site measurement photos must be provided.

- Site specifications: facade wall dimensions (height/width), column specifications (diameter/height), illuminated signage installation area on rooftop, and fountain pool dimensions (depth/area).

- Requirements: Specify the preferred effects for weekday, holiday, and national flag special modes, lighting schedule requirements, and zoning control needs.

- Compliance documentation: local project approval documents in Egypt, pre-approval guidelines for construction and installation permits, and regulatory requirements for electricity usage approvals.

- Upon receiving the client's materials, we will complete their organization and classification within 3 working days, with verification of completeness and identification of any missing items.

- For ambiguous or incomplete drawings, we will issue a 'Supplementary Documentation Notice'. The technical integration process will only commence after the client completes the required supplements.

- All original materials are archived and managed by our designated personnel, serving as the core reference for project design, construction, and acceptance.

- Drawing updates: Supplement missing lighting point diagrams and pipeline pre-embedded drawings with field survey data (if required), specifying all fixtures (including wall washers, recessed lights, and fountain lights) along with their installation points, spacing, and elevation.

- Parameter specifications: Dimensions shall be annotated in dual units (metric and imperial), with explicit international material standards (e.g., 304 stainless steel ASTM A240, No.8 channel steel ES 2629), waterproofing joints, and load-bearing verification data, compliant with Egyptian specifications.

- Visual aids: include dynamic lighting effect diagrams, beam coverage maps, and color point charts of the Egyptian flag to ensure drawings match visual requirements.

- Format specifications: Uniformly output AutoCAD.dwg and PDF versions with clear line layers, node details at a scale of ≥1:20, and reserved signature fields for client and third-party review.

- RGBW wall washer: Featuring 36W model specifications, calibrated installation angles, precision color reproduction of the Egyptian flag, and comprehensive facade lighting solutions.

- Column lighting system: Featuring integrated 24W RGBW spotlight installation with complementary lighting technology for uniform illumination.

- 24W RGBW recessed floor lamp: features integrated pre-installation (gravel bedding + concrete anchoring), IP67 waterproof rating, and anti-tap safety design technology.

- Fountain light: Integrated IP68 waterproofing, synchronized water jet effects, and underwater cable sealing technology.

- BERMILLAN illuminated signage: Featuring a height of 4-6 meters, 30-40cm thickness, 304 stainless steel casing, and 8mm channel steel structure technology, ensuring seamless integration with rooftop structures.

- Mode integration: Unifies the switching logic for three modes—daily (warm white light), festive (dynamic colored light), and Egyptian flag special (static/dynamic red, black, and white)—while synchronizing the operation sequence of all lighting fixtures.

- Zoned control: Design independent control modules for areas including canopies, facades, rooftops, and fountains, supporting both individual debugging and coordinated operation. The main controller stores ≥10 custom programs offline.

- Operation compatibility: Integrates manual buttons (distribution box) with timed automatic switching to simplify workflows and meet on-site maintenance requirements in Egypt.

- Cable selection standardization: Cables are categorized by region (RVV3×2.5mm² for wall-mounted lights, RVV3×1.5mm² for floor-mounted lights), with waterproof and shielded cables uniformly adopted to withstand Egypt's sandy climate.

- Integrated pipeline installation: aluminum alloy conduits for exterior facades, galvanized steel pipes for underground installations, and concealed steel structure pipelines for rooftop areas, all with uniform burial depth (≥50cm underground), fixed spacing (≤1.5m), and waterproof sealing standards.

- Distribution box integration: Install an IP65-rated outdoor waterproof distribution box (304 stainless steel) with built-in surge protectors (compatible with ±15% voltage fluctuations) and residual current devices (RCDs) (action current ≤30mA). Reserve 20% backup circuits and ensure unified grounding (resistance ≤4Ω).

- The completeness and accuracy of drawings and documentation, as well as the alignment of outcomes with requirements.

- Construction milestones, technical challenges and their solutions at each phase;

- Implementation of local compliance requirements in Egypt (GOEIC certification, construction permits, and observance of religious holidays);

- The client's required cooperation and the subsequent construction coordination procedures.

- On-site technical guidance: oversees the installation and calibration of lighting fixtures, pipeline installation, electrical wiring, and waterproofing to ensure compliance with design specifications.

- Effect debugging and control: Fully involved in the synchronized debugging of lighting effects, with a focus on calibrating the color accuracy of the Egyptian flag and ensuring smooth dynamic effects.

- Quality control: Regularly inspect the structural integrity of steel frameworks, corrosion protection coatings, and cable sealing conditions, ensuring compatibility with Egypt's high-temperature and sandy environment, and issue technical control reports.

- Issue rectification: For technical deviations during construction, promptly optimize the plan and guide corrective actions to ensure the project is implemented in compliance.

- Product specifications: Model WL-RGBW-36W,220V/50Hz AC, IP67-rated, featuring an anodized 6063 aluminum alloy enclosure with UV-resistant tempered glass, operating temperature range-25°C to +60°C, and a minimum surface finish of Ra≥88.

- Installation specifications: Aluminum alloy brackets arranged linearly (spacing ≤1.5m) with adjustable 0-45° angles, ensuring wall illumination ≥200lx. The cable tray shall be concealed and sealed.

- Effect Technology: Accurately reproduces the three colors of the Egyptian flag—red (#D81E05), white (#FFFFFF), and black (#000000)—with static vertical stripes (maintaining the flag's proportions) and dynamic scrolling effects, synchronized with other lighting fixtures.

- Column lights: 24W RGBW spotlight (30-45° projection angle) with flexible column wrap (15-20cm spacing), mounted on 304 stainless steel brackets with rust-proof and anti-corrosion treatment.

- Underground light: Model DL-RGBW-24W, IP67-rated, tempered glass panel (with a minimum pressure resistance of 200kg), installed in a pre-embedded pit using gravel and concrete, positioned at least 30cm above the curb, with monthly panel cleaning.

- Fountain light: IP68 waterproof rating, 18-24W power output, mounted 5-10cm above the pool bottom, features a dedicated underwater seal and synchronized illumination with water flow patterns.

- Specifications: Single character stands 4-6 meters tall with 30-40cm thickness, featuring a brushed 304 stainless steel casing and imported UV-resistant acrylic panel, offering IP65 waterproof rating.

- Lighting and Control: RGBW LED modules (12W per set), emitting 6000K true white light during regular days and full-color dynamic effects for festive occasions, integrated with a global control system.

- Steel structure: 8mm channel steel (ES 2629 standard), supported by independent frames and anchored with chemical bolts. With a tensile test strength of ≥15kN and wind resistance of ≥15m/s, the system features epoxy primer and fluorocarbon topcoat for corrosion protection.

- Exterior facade: The cable for the wall washer light runs through an aluminum alloy conduit, concealed along the waistline and ceiling, with the conduit and wall fully sealed.

- Ground: The buried lamp cables shall be installed in galvanized steel pipes (buried depth ≥50cm), with reserved maintenance access points and avoidance of municipal pipelines.

- Roof: Illuminated letter cables are concealed along the channel steel, with steel pipes spaced ≤1.5m apart to prevent trampling.

- Fountain zone: Underwater cable uses a dedicated sealing pipe, connected to the waterproof junction box by the pool edge, with double waterproof wrapping at the joint.

- Hardware integration: DMX512/Art-Net master controller, zone control module, and outdoor waterproof distribution box with offline program storage, supporting manual/automatic switching.

- Timed Control: Daytime Mode (warm white light on) → 23:00 automatic energy-saving → Holiday Mode (dynamic color lights) → Special Mode (national flag colors), with precise timing switching.

- Integrated system: Wall-mounted lights deliver full-color illumination across all zones, with synchronized activation of pillar lights, recessed lights, fountain lights, and illuminated signage—exhibiting zero latency and zero deviation.

- Product Compliance: All lighting fixtures and electrical equipment are CE and RoHS certified, with Egyptian GOEIC approval, and materials comply with local standards.

- Construction compliance: Avoid major Islamic holidays (Eid al-Fitr and Eid al-Adha), and complete building installation and power supply approvals in advance.

- Cultural compliance: The lighting effects and color displays conform to Islamic culture, contain no sensitive elements, and accurately and properly represent the colors of the national flag.

- Material Assurance: Constructed with 304 stainless steel, 6063 aluminum alloy, and UV-resistant acrylic, designed for Egypt's high-temperature sandy conditions with a service life exceeding 50,000 hours.

- Construction safeguards: steel structure tensile testing, waterproof seal inspection, and circuit continuity testing, with test reports issued for each procedure.

- Maintenance and Support: Monthly cleaning and quarterly inspection plans are provided, with reserved maintenance access routes and spare parts, along with overseas service network support.

- Part 1: Original documents and registration files (the client provides copies of the materials and the "Material Receipt Confirmation Form");

- Part 2: Integrated and optimized drawings (full set in CAD.dwg and PDF formats, including renderings);

- Part III: Technical Implementation Documents (Phase-by-Phase Implementation Guide, Lighting/Pipeline/Control Integration Plan);

- Part IV: Compliance and Inspection Documentation (Product Certification Certificate, Egyptian Market Access Certificate, Construction Inspection Report);

- Part 5: Operation and Maintenance Manual (including control system operation guide, daily maintenance procedures, and troubleshooting solutions).

- Draw in AutoCAD 2018 or later, save as.dwg, and provide a PDF version for client review.

- Sublayer line thickness: main structure lines 0.3mm, annotation lines 0.15mm, node detail drawings at a scale of ≥1:20.

- Illustration of dynamic effects for additional beams, marking the coverage areas and movement paths of effects such as scanning and gradient.

- The signature section includes designated spaces for design, review, and approval, with a reserved space for client confirmation.

- Embedded type: During the prefabrication of the canopy, holes are reserved with diameters 2-5mm larger than the lamp's outer diameter. After installation, neutral weather-resistant silicone sealant (ISO 11600 compliant) is used to fill the gaps, providing secondary waterproofing.

- Surface-mounted type: Custom-made 304 stainless steel bracket connected to the canopy structure via bolts (welded joints coated with anti-rust paint and fluorocarbon topcoat), with a load-bearing capacity of at least three times the lamp's weight.

- Cable selection: Use RVV3×1.5mm² waterproof cable (IP67) for power lines and shielded twisted pair RVSP2×0.75mm² (anti-interference) for signal lines. The cables shall be installed in galvanized steel pipes (for outdoor use) or PVC pipes (for indoor use).

- Pre-embedded requirements: All internal wiring must be embedded with the framework to prevent structural damage. Use outdoor waterproof junction boxes (IP65 rating), and double-wrap the connection points with waterproof tape and insulating tape.

- Debugging procedure: Test brightness and color consistency for each light → debug dynamic effects → record operational parameters → generate debugging report.

- Lamp selection: Choose an underwater waterproof RGBW fountain light (IP68-rated) with 18-24W power, designed for water depths of 0.5-1.5m, featuring dynamic lighting effects synchronized with water jet patterns.

- Installation method: Embedded in the fountain pool base, using stainless steel mounting brackets welded to the pre-buried components. The bracket height should be 5-10cm above the pool's sediment layer to prevent light obstruction.

- Waterproofing: The cable uses a dedicated underwater sealing connector, runs through the conduit to the waterproof junction box at the pool edge, and is reinforced at the connector with specialized underwater sealant to ensure no leakage during prolonged immersion.

- 24W RGBW compact spotlight: Install 2-4 units along the base perimeter of each column, with spacing adjusted according to diameter (2 units for ≤50cm, 4 units for50cm). Project 30-45° beams to ensure even illumination. Secure to ground or column base using stainless steel brackets with anti-corrosion treatment, fastened to the ground with expansion bolts.

- Column-mounted lights: Flexible RGBW column-mounted lights are selected, installed by wrapping them around the column body at 15-20cm intervals, with stainless steel clips securing both ends (the clips feature anti-slip soft pads to prevent surface scratches). The light fixtures are waterproofed at the connection points, and the cables are discreetly routed along the column to the base junction box, creating a complementary effect with the floodlight beams.

- Core product: Outdoor waterproof RGBW wall washer (Model: WL-RGBW-36W, ideal for Egyptian facade lighting). Featuring 36W power output and AC220V/50Hz input, it supports DMX512 control and integrates seamlessly with the project's control system for uniform wall illumination.

- Key specifications: IP67 waterproof rating, 120° illumination angle (ensuring no dark corners on walls), color rendering index Ra≥88, color temperature range 2700K (warm white) to 6000K (true white), RGBW four-color mixed light; the housing is made of anodized 6063 aluminum alloy, with UV-resistant tempered glass as the light-transmitting cover. Operating temperature: -25°C to +60°C, suitable for Egypt's high-temperature sandy climate. Supports precise color reproduction, capable of static display and dynamic switching of the Egyptian flag's three colors (red, white, and black).

- Certification requirements: Possess CE and RoHS international certifications, along with Egypt's GOEIC product approval, to ensure customs clearance compliance and local acceptance.

- Fixed installation: Aluminum alloy brackets shall be linearly arranged along the top, bottom, or waistline of the building facade with an installation spacing ≤1.5m to ensure uniform wall illumination (≥200lx) after light superposition. The brackets shall be fixed to the building structure using expansion bolts or chemical anchors, with anti-slip washers added to the contact surfaces to prevent surface scratches.

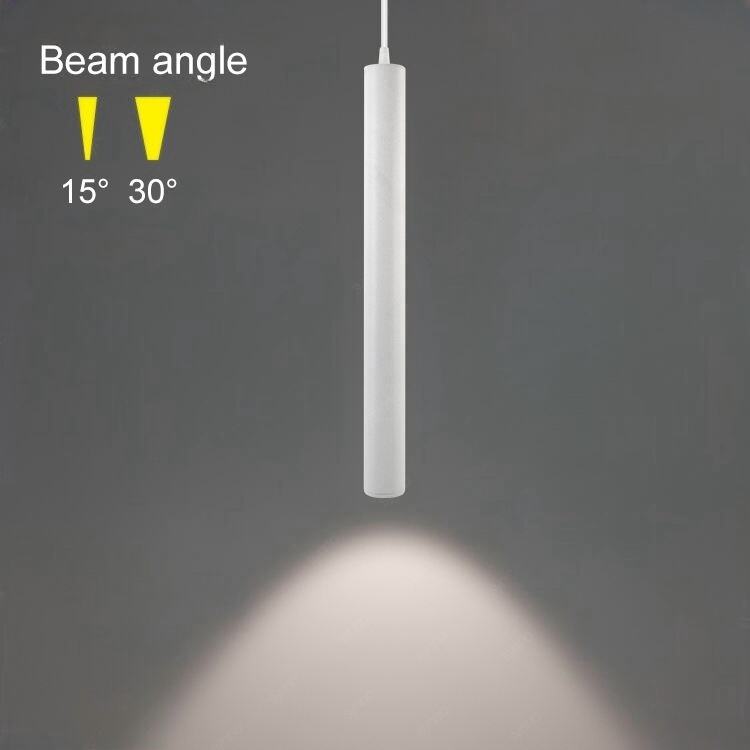

- Adjustable angle: The lamp's projection angle ranges from 0-45°, adjustable according to wall height (set to 20° for walls ≤5m,30° for walls5m) to ensure full coverage without blind spots.

- Cable installation: Power lines shall use RVV3×2.5mm² waterproof cables, while signal lines shall employ shielded twisted pair RVSP2×0.75mm². The cables shall be concealed in aluminum alloy conduits (with fixed spacing ≤1m), and the gaps between conduits and walls shall be sealed with weather-resistant silicone sealant. All cable connections shall be housed in waterproof junction boxes (IP65 rating) and wrapped with waterproof tape.

- Warm exterior lighting (daytime mode): Set to warm white light (2700K-3000K), with wall washers maintaining low brightness throughout the space. The even illumination creates a cozy and sophisticated commercial ambiance, complementing the warm glow of column and recessed lights.

- Dynamic RGB Color Effects (Festival Mode): Features gradient, chase, and flowing water effects. The wall wash lights operate synchronously across the entire wall, enabling color cycling and creating a 3D interplay with fountain lights and illuminated lettering.

- Egyptian flag color effects (special mode): The software precisely reproduces the red, white, and black colors of the Egyptian flag, supporting two display formats: static display (vertical color bars synchronized with the flag's proportions) and dynamic display (sequential color transitions across the entire wall). Ideal for major local festivals or celebrations.

- Environmental adaptation: Egypt experiences frequent sandstorms. Prior to installation, remove impurities from the installation area. After installation, clean the light-transmitting cover once monthly. Avoid direct exposure of the lamp to intense sunlight. A sunshade may be added to prevent light attenuation.

- Construction specifications: Comply with Egyptian Low Voltage Electrical Code (IEC 60364 Adapted Edition), with grounding resistance ≤4Ω and installation of residual current devices (RCDs) (trip current ≤30mA). Schedule construction outside religious holidays and obtain building facade construction permits in advance.

- Effect debugging: After installation, test the brightness and color consistency of each light, then conduct comprehensive linkage debugging, with a focus on calibrating the accuracy of the Egyptian flag colors to ensure uniform and error-free color display across the entire wall. Record the debugging parameters and prepare a specialized debugging report.

- Reserve maintenance access: The lighting fixtures are designed with a detachable structure, providing reserved maintenance access for easy module replacement and cleaning in the future. The cable tray is equipped with reserved maintenance openings to facilitate wiring maintenance.

- Core product: Outdoor waterproof RGBW ground-mounted light (Model: DL-RGBW-24W, suitable for export and Egyptian markets). Features 24W power output, AC220V/50Hz input voltage (directly compatible with Egyptian mains), DMX512 control support, and full compatibility with the project's integrated control system.

- Key specifications: IP67-rated protection (dust and water resistant, withstands Egyptian sandstorms and short-term water accumulation); adjustable light emission angle (15-60°); color rendering index (Ra) ≥85; color temperature range (warm white: 2700K to cool white: 6000K); RGBW four-color mixed light; dual-mode switching (day/night/festival); 304 stainless steel casing with brushed finish; tempered glass panel (anti-glare, pressure resistance ≥200kg); operating temperature-20℃ to +60℃; suitable for Egyptian high-temperature climate.

- Certification requirements: Possess CE and RoHS international certifications, along with Egypt's GOEIC product approval, to ensure customs clearance compliance and local acceptance.

- Pre-embedded installation: Excavate a pre-embedded pit (10-15cm larger than the lamp's outer diameter, with a depth of at least 10cm above the lamp's height) in advance. Lay a 10cm gravel base layer for drainage and water resistance, then pour a 5cm concrete base to secure the lamp, ensuring a level and stable installation.

- Lamp Fixation: Secure the lamp base to the concrete foundation using stainless steel expansion bolts. Seal the gap between the base and the ground with neutral weather-resistant silicone sealant (to prevent rainwater and dust infiltration). Install the lamp away from densely pedestrianized main passages, maintaining a minimum distance of ≥30cm from the curb. The spacing should be determined based on lighting requirements (typically 2-3m per unit to form a uniform light strip).

- Cable installation: Use RVV3×1.5mm² waterproof cables (IP67) for wiring, and shielded twisted pair cables (RVSP2×0.75mm²) for signal lines. Embed the cables in galvanized steel pipes underground (buried at least 50cm deep to prevent damage from traffic) and connect them in waterproof junction boxes (IP65). Apply waterproof wrapping to the cables, and provide access ports in the junction boxes for future maintenance.

- Environmental Adaptation: Egypt experiences frequent sandstorms. Prior to installation, remove impurities from the pre-buried pit. After installation, clean the panel dust periodically (once monthly). Avoid installing in low-lying or waterlogged areas. If the site is prone to water accumulation, additional drainage pipes must be installed to prevent prolonged immersion of the fixtures.

- Construction specifications: Comply with the Egyptian Low Voltage Electrical Code (IEC 60364 Adapted Edition), with grounding resistance ≤4Ω, and install a residual current device (RCD) (trip current ≤30mA). Schedule construction outside religious holidays, obtain prior approval for underground pipeline inspection, and avoid damaging municipal pipelines.

- Safety protection: Warning signs must be affixed to tempered glass panels to prevent pedestrian trampling and damage; wear-resistant treatment should be applied at cable conduit entry points to avoid scratches on cable insulation layers caused by steel pipe edges.

- Debugging and Maintenance: After installation, conduct individual lamp tests for brightness and color consistency, and debug the coordination effects with canopy lights, column lights, and illuminated letters. Reserve maintenance access channels, and design the lamps with a detachable structure to facilitate module replacement and cleaning in later stages.

- Lamp selection: Choose an underwater waterproof RGBW fountain light (IP68-rated) with 18-24W power, designed for water depths of 0.5-1.5m, featuring dynamic lighting effects synchronized with water jet patterns.

- Installation method: Embedded in the fountain pool base, using stainless steel mounting brackets welded to the pre-buried components. The bracket height should be 5-10cm above the pool's sediment layer to prevent light obstruction.

- Waterproofing: The cable uses a dedicated underwater sealing connector, runs through the conduit to the waterproof junction box at the pool edge, and is reinforced at the connector with specialized underwater sealant to ensure no leakage during prolonged immersion.

- 24W RGBW compact spotlight: Install 2-4 units along the base perimeter of each column, with spacing adjusted according to diameter (2 units for ≤50cm, 4 units for50cm). Project 30-45° beams to ensure even illumination. Secure to ground or column base using stainless steel brackets with anti-corrosion treatment, fastened to the ground with expansion bolts.

- Column-mounted lights: Flexible RGBW column-mounted lights are selected, installed by wrapping them around the column body at 15-20cm intervals, with stainless steel clips securing both ends (the clips feature anti-slip soft pads to prevent surface scratches). The light fixtures are waterproofed at the connection points, and the cables are discreetly routed along the column to the base junction box, creating a complementary effect with the floodlight beams.

- Core product: Outdoor waterproof RGBW ground-mounted light (Model: DL-RGBW-24W, suitable for export and Egyptian markets). Features 24W power output, AC220V/50Hz input voltage (directly compatible with Egyptian mains), DMX512 control support, and full compatibility with the project's integrated control system.

- Key specifications: IP67-rated protection (dust and water resistant, withstands Egyptian sandstorms and short-term water accumulation); adjustable light emission angle (15-60°); color rendering index (Ra) ≥85; color temperature range (warm white: 2700K to cool white: 6000K); RGBW four-color mixed light; dual-mode switching (day/night/festival); 304 stainless steel casing with brushed finish; tempered glass panel (anti-glare, pressure resistance ≥200kg); operating temperature-20℃ to +60℃; suitable for Egyptian high-temperature climate.

- Certification requirements: Possess CE and RoHS international certifications, along with Egypt's GOEIC product approval, to ensure customs clearance compliance and local acceptance.

- Pre-embedded installation: Excavate a pre-embedded pit (10-15cm larger than the lamp's outer diameter, with a depth of at least 10cm above the lamp's height) in advance. Lay a 10cm gravel base layer for drainage and water resistance, then pour a 5cm concrete base to secure the lamp, ensuring a level and stable installation.

- Lamp Fixation: Secure the lamp base to the concrete foundation using stainless steel expansion bolts. Seal the gap between the base and the ground with neutral weather-resistant silicone sealant (to prevent rainwater and dust infiltration). Install the lamp away from densely pedestrianized main passages, maintaining a minimum distance of ≥30cm from the curb. The spacing should be determined based on lighting requirements (typically 2-3m per unit to form a uniform light strip).

- Cable installation: Use RVV3×1.5mm² waterproof cables (IP67) for wiring, and shielded twisted pair cables (RVSP2×0.75mm²) for signal lines. Embed the cables in galvanized steel pipes underground (buried at least 50cm deep to prevent damage from traffic) and connect them in waterproof junction boxes (IP65). Apply waterproof wrapping to the cables, and provide access ports in the junction boxes for future maintenance.

- Environmental Adaptation: Egypt experiences frequent sandstorms. Prior to installation, remove impurities from the pre-buried pit. After installation, clean the panel dust periodically (once monthly). Avoid installing in low-lying or waterlogged areas. If the site is prone to water accumulation, additional drainage pipes must be installed to prevent prolonged immersion of the fixtures.

- Construction specifications: Comply with the Egyptian Low Voltage Electrical Code (IEC 60364 Adapted Edition), with grounding resistance ≤4Ω, and install a residual current device (RCD) (trip current ≤30mA). Schedule construction outside religious holidays, obtain prior approval for underground pipeline inspection, and avoid damaging municipal pipelines.

- Safety protection: Warning signs must be affixed to tempered glass panels to prevent pedestrian trampling and damage; wear-resistant treatment should be applied at cable conduit entry points to avoid scratches on cable insulation layers caused by steel pipe edges.

- Debugging and Maintenance: After installation, conduct individual lamp tests for brightness and color consistency, and debug the coordination effects with canopy lights, column lights, and illuminated letters. Reserve maintenance access channels, and design the lamps with a detachable structure to facilitate module replacement and cleaning in later stages.

- Daytime mode: The system employs warm-toned lighting (2700K-3000K) with constant low-intensity floodlights on the canopy. Column and pillar lights emit warm white light, synchronized with the fountain lights' soft illumination. RGBW wall washers provide uniform warm white lighting across the walls, while recessed lights offer supplementary warmth. This creates a sophisticated and dignified commercial ambiance, perfectly suited for daily operations.

- Festival Mode: Features full-color dynamic effects with synchronized operation of canopy spotlights, fountain lights, column lights, and recessed lights. The wall washer creates RGB dynamic color cycles (gradients, chases, etc.) across entire walls, while pillar embrace lights and floodlights form three-dimensional colored effects. Fountain lights change colors with water column undulations. Customizable festival-specific light sequences are supported, automatically switching to energy-saving daily mode after 23:00.

- Egyptian Flag Special Mode: The control software precisely replicates the red, white, and black colors of the Egyptian flag, with the wall washer lights synchronizing the flag's colors across the entire wall (as static vertical stripes or dynamic flowing effects). Other lights automatically switch to warm white light for enhanced ambiance. This mode is ideal for major local festivals and celebrations, highlighting the cultural relevance of the region.

- Daytime mode: The space features warm-toned lighting (3000K) with low-intensity floodlights permanently activated. Both column and pillar lights emit warm white light, while fountain lights synchronize to create a soothing ambiance. This design cultivates a dignified commercial atmosphere, perfectly suited for daily operations.

- Festival Mode: Switches to full-color dynamic effects with synchronized operation of canopy spotlights, fountain lights, and column lights. Features color gradients, synchronized chasing, and three-dimensional lighting effects created by pillar-hugging lights and floodlights. Fountain lights change colors with water flow. Customizable festival-specific light sequences are supported. After 23:00, it automatically switches to daily mode for energy-saving operation.

- Energy-efficient lighting: Choose LED RGB spotlights with a luminous flux of ≥120lm/W and a power factor of ≥0.9, delivering over 60% energy savings compared to traditional lighting while offering a lifespan of ≥50,000 hours.

- Energy-saving mode: Timed on/off with automatic brightness adjustment, automatically cuts power after 11 PM, saving about 3 hours of electricity daily.

- Energy efficiency: Low-loss cables (≤3% transmission loss) and surge protection devices (SPD) in control boxes extend equipment lifespan.

- Installation methods: curtain wall embedded, rooftop suspension, or column-mounted systems, with a third-party structural load-bearing verification report required.

- Safety requirements: Design according to local wind load standards (wind load ≥0.7kN/㎡ for high-rise CBD buildings), install wind-resistant tie rods, and conduct wind and seismic tests upon completion.

- Cabling standards: separate wiring from building's power and low-voltage systems, use Ethernet cables for ≤100m transmission, switch to fiber optics for longer distances, and locate control rooms in moisture-proof indoor zones.

- Appearance requirements: The frame width should be ≤5mm to ensure harmony with the building facade and avoid compromising the overall aesthetic.

- Installation options: wall-mounted or bracket-mounted. For small-pitch screens (P2.5 and below), they can be embedded in partition walls.

- Viewing distance requirements: The viewing distance should be 100-150 times the pixel pitch (e.g., for a P2.5 screen, the viewing distance should be ≥2.5 meters). Direct sunlight should be avoided by installing a blackout curtain.

- Cabling requirements: The wiring shall be concealed through ceiling or floor conduits to maintain a clean office environment and ensure seamless integration with conference systems and computers.

- Operation requirements: The control software simplifies the interface and supports one-click switching between presentation mode and muted playback.

- Environmental adaptation: Install a removable dust cover and clean it once a month; select UV-resistant panels to prevent aging from prolonged exposure to sunlight.

- Electrical specifications: 220V/50Hz power supply, with high-precision voltage stabilizers installed in remote areas (self-adaptive within ±10% voltage fluctuation range).

- Compliance requirements: Obtain local construction and installation permits and electricity approvals in advance, and schedule construction outside religious holidays.

- Display content must comply with Islamic culture. Sensitive images and text are prohibited. You can schedule to block inappropriate content.

- Core specifications: 4-6m character height, 30-40cm thickness, featuring white luminescent base. The casing is constructed with 304 stainless steel (compliant with ASTM A240 standards) and brushed surface finish, combining premium texture with weather resistance for optimal performance in Egypt's scorching sandstorms.

- Lighting configuration: The system features an embedded RGBW LED module with 12W power output and a color rendering index (CRI) of ≥85. In daily mode, it emits 6000K pure white light (brightness ≥1500cd/㎡) for clear visibility at a distance. During festive events, it switches to full-color lighting effects with dynamic features including gradient transitions, jump transitions, and synchronized effects.

- Technical specifications: The panel is formed by laser cutting and slotting, reinforced with seamless welding, and features imported UV-resistant acrylic (laser-engraved and sealed). With an IP65 waterproof rating, it withstands intense Egyptian UV radiation and sand erosion, preventing yellowing and cracking.

- Construction material: 8mm thick channel steel (compliant with Egypt's Building Steel Standard ES 2629) is welded to form an independent support frame. Each unit features a dedicated steel structure to ensure uniform load distribution, meeting the wind speed requirement of ≥15m/s in certain Egyptian regions.

- Anti-corrosion treatment: The process follows 'rust removal → epoxy primer (≥80μm thickness) → fluorocarbon topcoat (≥60μm thickness)', with additional anti-corrosion repainting at welded joints to prevent rust caused by dust and high temperatures, thereby extending service life.

- Fixation method: Securely connect to the roof structure embedded components using chemical anchors. Conduct tensile tests at each connection point with a minimum strength of 15kN. Submit third-party wind and seismic load calculations to ensure compliance with Egypt's Building Structure Safety Code.

- Distribution Cabinet: Features an outdoor waterproof distribution cabinet (IP65 rating) with built-in circuit breakers, surge protectors (SPD) compatible with ±15% voltage fluctuations in Egypt, and contactors. It includes a 20% backup circuit. The cabinet is constructed from 304 stainless steel and equipped with a dust-proof mesh for easy maintenance.

- Cables and Pipelines: Power lines shall use RVV3×2.5mm² waterproof cables (IP67), while signal lines shall employ shielded twisted pair RVSP2×0.75mm² (anti-interference, to prevent signal attenuation in dusty environments). All wiring shall be installed in galvanized steel pipes with a fixed spacing of ≤1.5m. Roof pipelines shall be protected against foot traffic, and wall penetrations shall be sealed with waterproof sleeves, complying with Egyptian Low Voltage Electrical Code (IEC 60364 Adapted Edition).

- Safety protection: Ensure grounding resistance ≤4Ω and install a residual current device (RCD) with an operating current ≤30mA. Waterproof wrapping (using waterproof tape and insulating tape for dual protection) must be applied to cable joints to prevent rainwater and dust from causing short circuits.

- Control Architecture: The system integrates with the DMX512/Art-Net control system to enable synchronized operation of canopy spotlights, pillar lights, and fountain lights. It also supports zoned independent control, allowing individual switching of BERMILLAN illuminated lettering modes.

- Mode switching: Features preset dual modes (daylight and holiday), with the main control software automatically switching between them (synchronized with the project's overall schedule, switching to daylight mode after 23:00 for energy-saving operation). The distribution box panel includes a manual switch button for temporary debugging and emergency operations.

- Program storage: The main controller stores over 10 holiday light programs offline, supporting custom effects editing via Madrix control software to match local Egyptian festival ambiance, eliminating the need for continuous computer connection.

- Certification Compliance: Materials including 304 stainless steel, Grade 8 channel steel, and electrical equipment must obtain CE and RoHS certifications, with additional Egyptian product access certification (GOEIC). For steel structures and electrical installations, third-party inspection reports are required to ensure compliance with Egyptian building and electrical codes.

- Cultural adaptation: Schedule construction periods to avoid major Islamic holidays (e.g., Eid al-Fitr, Eid al-Adha), and proactively coordinate with local authorities to obtain building installation permits and electrical approval procedures, thereby preventing non-compliant construction.

- Protection during installation: Operators shall wear dust-proof and sun-protective equipment. After welding operations, weld slag shall be promptly removed and anti-corrosion treatment shall be applied to prevent accelerated rusting of the welded joints due to sand and dust. During installation, the building facade and roof structure shall be protected to avoid secondary damage.

- Maintenance Plan: The illuminated sign panel is designed with a detachable structure, with reserved maintenance access channels and steel structure interfaces for ladder installation. Dust-proof nets, illuminated sign panels, and junction boxes shall be cleaned monthly. Circuit connections, structural integrity of the steel frame, and anti-corrosion coatings shall be inspected quarterly to accommodate Egypt's climate characteristics of frequent sandstorms and high temperatures.

- Distribution cabinet: Features an outdoor waterproof distribution cabinet (IP65-rated, designed for Egypt's high-temperature and dusty conditions), equipped with built-in circuit breakers, surge protectors (SPD, compatible with Egypt's voltage fluctuations), and contactors. It supports 220V/50Hz local voltage and includes a reserved backup circuit.

- Cable selection: The power supply uses RVV3×2.5mm² waterproof cable, while the signal line employs shielded twisted pair RVSP2×0.75mm² (anti-interference, designed to prevent signal attenuation in Egyptian sandstorm conditions). Both cables are installed through galvanized steel conduits.

- Pipeline installation: The pipeline shall be concealed along the steel structure with steel pipes spaced ≤1.5m apart. Roof pipelines require anti-pedestrian protection, and wall penetrations must be sealed with waterproof sleeves to prevent rainwater infiltration.

- Control Architecture: The system integrates with the DMX512/Art-Net control system for the entire project, enabling synchronized control of canopy spotlights, pillar lights, and other fixtures. It supports zoned independent control (with separate switching of BERMILLAN illuminated lettering modes).

- Mode switching: Features preset dual modes (daytime/festival), with scheduled switching via master control software (synchronized with project timeline) and manual button operation (pre-installed buttons on distribution box panel).

- Program storage: The main controller stores over 10 holiday light programs offline, supports custom effects through software editing, and adapts to the festive atmosphere of Egypt.

- Material compliance: 304 stainless steel meets ASTM A240 standards, section 8 channel steel complies with Egypt's Building Steel Specifications (ES 2629), and all electrical equipment must hold CE and RoHS certifications along with local product approval certificates in Egypt.

- Electrical compliance: Adherence to Egypt's Low Voltage Electrical Code (IEC 60364 Adapted Edition), with cable installation meeting fireproof and leakage current protection requirements, ground resistance ≤4Ω, and installation of a residual current device (RCD) with an operating current ≤30mA.

- Structural compliance: The steel structure design complies with Egyptian wind load standards (applicable to regions with wind speeds ≥15m/s), including wind and seismic load calculations, with a third-party inspection report submitted.

- Protective measures: During construction, avoid Egyptian religious holidays; workers must wear dust-proof and sun-protective gear, and promptly apply anti-rust treatment to welding areas to prevent accelerated corrosion from sand and dust.

- Waterproof and dustproof: The illuminated letter panel is securely sealed with a stainless steel casing, while the junction box and distribution box are fitted with dust-proof nets. Monthly cleaning is required to ensure compatibility with Egypt's sandy environment.

- Design considerations: BERMILLAN's illuminated signage features detachable panels with reserved maintenance access, and steel structure interfaces for ladder installation, facilitating future LED module replacement and cleaning.

- Structural safety: The design is based on local meteorological data (e.g., wind speeds ≥15 m/s in some Egyptian regions), with illuminated letter weights kept within the roof's load-bearing capacity.

- Waterproof sealing: Neutral weather-resistant silicone sealant is applied to gaps, with IP65-rated junction boxes and power cables routed through waterproof conduits.

- Electrical safety: Low-voltage (12V/24V) LED chips are used, with the control box installed in a waterproof distribution box either indoors or on the roof, and equipped with a residual current device (RCD).

- Maintenance access: The illuminated sign features a detachable design to allow easy replacement of light bulbs.

- Projection specifications: 1080P/4K resolution, outdoor brightness ≥10,000 lumens (daytime visibility), contrast ratio ≥20,000:1, and color accuracy ≥95%.

- Lens specifications: Projection ratio 1.2:1 to 2.0:1, with 1.2x optical zoom and adjustable horizontal/vertical tilt.

- Control parameters: Supports synchronous/asynchronous control, multi-machine fusion splicing (≤16 units), equipped with professional fusion software, and features interactive sensing interface.

- Environmental parameters: Operating temperature-20℃ to +50℃, outdoor protection rating IP54 (IP65 with protective enclosure).

- Installation location: Choose an open area with unobstructed view, ensuring the projection distance matches the lens's projection ratio. For outdoor installations, a waterproof and dustproof enclosure with a cooling system must be added.

- Projection surface requirements: smooth and non-reflective. We recommend applying specialized projection paint (gain ≥1.2) to enhance image clarity.

- Calibration and adjustment: For multi-camera stitching, perform fusion calibration (overlap ≤10%); 3D effects require stereo calibration to prevent ghosting.

- Maintenance requirements: Regular cleaning of lenses and filters, with monthly inspections of outdoor equipment to check waterproofing and heat dissipation.

- Climate adaptation: Equipped with a high-performance cooling fan (compatible with temperatures up to +50°C) and a reinforced filter mesh (sand and dust resistant), with weekly filter cleaning.

- Voltage compatibility: The power module supports 220V/50Hz, with an added voltage stabilizer (tolerating ±15% voltage fluctuation) to prevent equipment damage.

- Projection timing: Due to intense daytime sunlight, it is recommended to project from evening (after 18:00) until night, or use a high-brightness projector with ≥20,000 lumens.

- Cultural Compliance: 3D animation content must comply with Islamic cultural norms, avoiding sensitive elements such as pigs and crosses, and must undergo prior content review.

- Attachment 1: Complete set of CAD drawings (.dwg and.pdf formats);

- Attachment 2: Equipment Technical Specifications (including international certifications such as CE and RoHS), detailing parameters for CBDBERMILLAN specialized lighting fixtures (RGBW wall washer, 24W RGBW spotlight, pillar-mounted light, fountain light, and 24W RGBW floor-mounted light) and BERMILLAN illuminated signage (featuring steel structures and electrical systems).

- Attachment 3: Construction flowchart and schedule plan;

- Annex 4: Construction Permit Application Guide for Egypt Region;

- Appendix 5: After-sales Service Plan (including overseas maintenance network details).

Technical Scheme and Implementation Guide of Outdoor Photoelectric System Project for Commercial MALL

Document Purpose: Bid Coordination, Project Implementation, Technical Briefing

Application scenarios: facade and rooftop lighting projects, overseas projects in Egypt

Core scope: CAD drawing integration, RGBW series lighting fixtures (wall washer lights, floodlights, pillar-mounted lights, recessed lights, fountain lights), BERMILLAN rooftop illuminated signage, control systems, and pipeline/circuit engineering

Compatibility standards: Complies with international engineering installation specifications, compatible with Egypt's local voltage (220V/50Hz), climatic conditions, and cultural requirements, while strictly adhering to Egypt's building, electrical, and product access compliance standards.

1. Project Pre-Requirements: List of original documents required by the client

To ensure our accurate execution of drawing review, technical integration, pipeline planning, and effect design, the client must submit the following original documents in advance. We will register and archive them uniformly as the basis for technical design.

1.1 Core Drawing Materials

1.2 Basic Parameter Data

1.3 Data Handover and Registration Process

2. Decomposition of Project Implementation Phase (Core Work Content of Our Team)

Stage 1: Data registration and drawing integration and optimization

2.1.1 Data Registration and Archiving

We systematically register the original drawings and technical parameters provided by clients, maintaining both electronic and paper archives. Each document is labeled with version number, receipt date, and purpose category to ensure traceability and verifiability, thereby preventing design deviations.

2.1.2 CAD Drawing Integration and Optimization

Based on the client's original drawings, we have completed the following integration and optimization work to establish a unified project construction drawing system:

Phase 2: Technical Solution Design and Integration

2.2.1 Technical Integration of Lighting Systems

By integrating client requirements with Egypt's climate and regulatory compliance standards, we develop standardized technical documentation through comprehensive solutions for all lighting fixtures, covering selection, installation, and performance optimization.

2.2.2 Control System Technology Integration

The DMX512/Art-Net control system integrates global linkage technology to enable precise mode switching:

Phase 3: Pipeline Circuit System Design and Integration

2.3.1 Pipeline Circuit Planning and Design

We have completed the integrated design and integration of pipeline and electrical systems, ensuring safety, concealment, and weather resistance, in compliance with building structures and Egyptian Electrical Code (IEC 60364 Adapted Edition).

2.3.2 Circuit Safety and Compliance Integration

All circuit designs comply with Egypt's 220V/50Hz voltage standard, incorporating short-circuit protection, leakage current protection, and lightning protection technologies. An electrical compliance test report has been submitted to ensure local regulatory approval.

Phase 4: Technical Briefing and Plan Confirmation

We will compile the consolidated drawings, technical specifications, and pipeline/circuit design documents into a comprehensive manual, providing the client with a thorough technical briefing to clarify and confirm the following:

Stage 5: Construction Coordination and Technical Control

We provide end-to-end technical support, implement technical solutions, and ensure construction quality control.

III. Detailed Technical Specifications of the Core System

3.1 Lighting System Design (Egypt Scenario)

3.1.1 RGBW Wall Lighting System

3.1.2 Column Lights + Ground-embedded Lights + Fountain Lights System

3.1.3 BERMILLAN Roof Illumination System

3.2 Pipeline Circuit and Control System Integration Solution

3.2.1 Integrated Design of Pipeline and Circuit

Plan uniformly by area to ensure concealed, secure, and weather-resistant cabling.

3.2.2 Control System Interconnection Scheme

With Madrix professional control software, achieve "one-click switching and full-domain synchronization":

IV. Compliance and Quality Assurance in Egypt

4.1 Compliance Requirements Implementation

4.2 Quality Assurance Measures

V. List of Deliverables

Upon project completion, we will deliver the following deliverables in both Word and PDF formats for client archiving and acceptance.

Applicable scenarios: Large-scale projects in Central Business District (CBD), office environments, and overseas projects (Egypt)

Core components include: CAD drawing systems, RGB spotlight systems, outdoor display screens, rooftop illuminated signage, and 3D projection systems.

Compatibility standards: Complies with international engineering installation specifications, compatible with local Egyptian voltage (220V/50Hz), climate, and cultural requirements.

1. CAD Drawing System (High Ceiling Canopy RGB Floodlight Project)

1.1 Bill of Works and Core Requirements

Drawing type |

Core annotation content |

Key points of foreign trade adaptation |

ichnography |

Rain canopy dimensions, RGB spotlight installation points (spacing and edge distance), wiring routing, and control box location |

Dual unit labeling (metric: mm/m; imperial: inch/ft) with clear point coordinate reference |

vertical view |

Canopy height, spotlight installation elevation, beam projection angle, and architectural facade integration |

Mark the dynamic coverage range of the beam and match the curtain wall decoration style |

Curtain Wall Picture |

Curtain Wall Material, Spotlights and Curtain Wall Fixing Method, Waterproof Sealing Joints, Hole Size |

Specify the material's international standard number (e.g., ASTM A240 for 304 stainless steel) |

Install node diagram (Important) |

1. Spotlight installation (embedded/surface-mounted): bracket dimensions, screw specifications, structural connection details; 2. Curtain wall joints: sealant type, load-bearing verification annotations; 3. Wiring installation: conduit routing, pre-buried paths, waterproof junction boxes; 4. Control box: mounting method, rain/dustproofing treatment |

The node detail drawing includes a material weather resistance description, designed for Egypt's high-temperature sandy environment. |

1.2 Drawing Standards

2. RGB Floodlighting System for High-ceilinged Canopies (Installation, Control, and Energy Efficiency)

2.1 Construction and Installation Plan

2.1.1 Lighting Installation

2.1.2 Line Construction

2.1.3 Commercial Exterior Lighting Installation (Key Focus)

2.1.3.1 Installation of Fountain Lights

2.1.3.2 Column Lighting Installation (Spotlight + Column Bracket Lights)

2.1.3.3 Installation of RGBW Wall Lighting (Special Project, Formerly Known as Narcissus Lighting)

2.1.3.3.1 Recommended Products and Core Parameters

2.1.3.3.2 Installation Method

2.1.3.3.3 Implementation Plan for Effectiveness

2.1.3.3.4 Installation and Usage Notes

2.1.3.4 Installation of 24W RGBW Underground Lights (Special Project)

2.1.3.4.1 Recommended Products and Core Parameters

2.1.3.4.2 Installation Method

2.1.3.4.3 Installation and Usage Notes

2.1.3.1 Installation of Fountain Lights

2.1.3.2 Column Lighting Installation (Spotlight + Column Bracket Lights)

2.1.3.3 Installation of 24W RGBW Underground Lights (Special Project)

2.1.3.3.1 Recommended Products and Core Parameters

2.1.3.3.2 Installation Method

2.1.3.3.3 Installation and Usage Notes

2.2 Dynamic Effects and Playback Methods

2.2.1 Core Effect Types

Supports dynamic effects such as scanning, gradient, chase, jump, and music synchronization. To meet commercial center requirements, three preset basic modes are available: canopy spotlights, fountain lights, column lights, wall wash lights, and floor-mounted lights with synchronized control.

2.2.2 Playback Control Logic

The system supports scheduled switching (with minute-level precision) through preset effect sequences in the control software. The main controller stores over 10 customizable programs offline, eliminating the need for prolonged computer connections. For exterior facades, a new zone control function has been introduced, allowing independent operation of fountain lights, column lights, or full ensemble coordination to meet diverse scene requirements.

2.3 Control System Design

control method |

technical parameter |

applicable scene |

program control (core) |

The system employs a DMX512/Art-Net control system with professional control software (Madrix), supporting program editing, import/export, and featuring an LCD display on the main controller. A newly added zone control module enables independent or synchronized lighting control for areas such as canopies, fountains, and columns, meeting the collaborative lighting requirements of exterior facades. |

CBD large-scale projects and festive atmosphere creation |

manual control |

The control panel features an effect toggle button and a brightness adjustment knob for easy operation. |

Temporary debugging, emergency switch |

Smart Control (Optional) |

Connect to the IoT platform, support remote control via mobile app and voice control, equipped with a brightness sensor (automatic dimming) |

High-end office space, smart campus |

2.4 Energy-saving and Environmental Protection Design

III. Outdoor Display System (Technical Specifications and Installation Guidelines)

3.1 Core Technical Parameters (Foreign Trade Adapted Version)

Parameter category |

key index |

Egypt Project Adaptation Notes |

Display parameters |

Pixel pitch: P3/P4 (common for outdoor use); Resolution: Customizable (calculated by size); Brightness: ≥5000cd/㎡; Contrast: ≥3000:1; Viewing angle: Horizontal ≥160°, Vertical ≥140° |

High brightness mode adapts to bright Egyptian light conditions, ensuring clear visibility during the day |

performance parameter |

Refresh rate ≥3000Hz; response time ≤10ms; grayscale level ≥16bit; lifespan ≥100000 hours |

High refresh rate with no blur, compatible with dynamic ads and live events |

Protection parameters |

Protection rating IP66; Operating temperature-30°C to +60°C; Anti-glare and UV protection |

Dustproof and waterproof, resistant to the high-temperature and sandy climate of Egypt |

controlling parameter |

Control mode: Synchronous/Asynchronous dual mode; Interface: HDMI/DP/Network port; Supports remote cloud control and USB drive import |

The asynchronous mode adapts to unstable network areas and supports offline playback |

3.2 Installation Notes for Different Scenarios

3.2.1 CBD Large-scale Projects

3.2.2 Office Scenario

3.2.3 Special Requirements for the Egyptian Region

4. Roof Illuminated Signage System (Manufacturing, Installation and Regional Adaptation)

4.1 Core Program (BERMILLAN Special Project for Illuminated Characters)

4.1.1 Specifications and Material Requirements

4.1.2 Steel Structure Design (Special Project for No.8 Channel Steel)

4.2 Electrical and Control System Configuration

4.2.1 Electrical System (Compliant with Egyptian 220V/50Hz Standards)

4.2.2 Control System

4.3 Regional Compliance and Installation & Maintenance Guidelines in Egypt

4.3.1 Technical Compliance Requirements

4.3.2 Key Points of Installation and Maintenance

4.4 General Lighting Solutions (Supplementary Reference)

For additional small LED signage requirements in the project, 304 stainless steel (Egyptian scenarios preferred) with front-lit mode and 15-25cm thickness is recommended. The steel structure uses angle steel supports, while the electrical system shares control circuits with BERMILLAN LED signs. Installation options include wall mounting (expansion bolts/chemical anchors, tensile strength ≥10kN) or parapet wall installation. Gaps are sealed with weather-resistant silicone sealant, achieving IP65 waterproof rating to ensure style consistency and synchronized control with the specialized design.

4.2.1 Electrical System

4.2.2 Control System

4.3.1 Technical Specification Adaptation

4.3.2 Installation and Maintenance Notes

V. 3D Projector System (Technical Specifications, Effects and Regional Adaptation)

5.1 Effect Classification and Application Scenarios

Effect type |

Render |

Applicable items |

3D static projection |

3D Modeling of Building Facade and Sculpture Projection to Create Immersive Visual Impact |

CBD building lighting, cultural venues |

3D dynamic projection |

3D animation playback, audience interaction projection (infrared/radar sensing), multi-camera fusion splicing (ultra-large screen) |

Festival events, commercial promotions |

special effect projection |

Water mist projection, holographic projection (with holographic film), and suspended stereoscopic visual effects |

High-end launch event, cultural tourism project |

5.2 Core Technical Indicators

5.3 Installation and Usage Notes

5.4 Special Requirements for Use in Egypt

VI. List of Attachments (Required for Bidding)

| (Note: Some content in the document may be generated by AI)